What are composite fabrics?

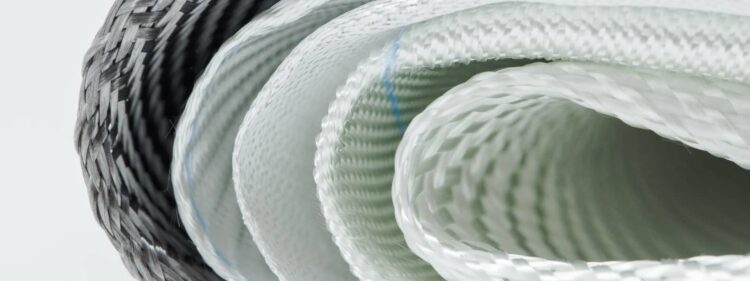

Composite fabrics, otherwise called “composites” are made from two or more different types of fibers that are combined to create a single fabric. The fibers can be combined in several ways, including weaving, knitting, or bonding. Composite fabrics offer a number of benefits over traditional fabrics, including increased strength, durability, and resistance to wrinkles and stains.

Composites have become popular thanks to their strength, lightness, and relatively low associated costs. Composite fabrics are used in sports equipment, cars, interiors, and exteriors, as well as domestic appliances and household objects, vehicles, etc. Composites are gradually replacing traditional materials such as steel and aluminum. Fiber-reinforced composites like carbon fiber and fiberglass give up new design opportunities for engineers as composite costs come down and design flexibility improves.

Fiberglass composites

Invented in the 1930s, glass fiber composites were originally designed for military use during WWII before becoming more widely used in the 1950s. Naturally, fiberglass composites have advanced significantly over the years, and their use has spread to a wide range of industries. Fiberglass composites, in general, have multiple benefits including more traditional materials like wood, steel, or concrete.

These benefits include:

- Especially for complex shapes, it’s cost-effective;

- Corrosion protection;

- Strong structural integrity;

- Superior weight-to-strength ratio;

- Temperature of high heat distortion;

- Non-conductive electrically;

- Tolerances can be molded to within a few millimeters.

Also Read: Fiberglass Roofing Sheet

How glass fiber composites are made?

Glass fiber-reinforced composites are made up of glass fibers embedded in a matrix. The matrix is typically a plastic resin such as polyester, epoxy, or polyamide. The glass fibers provide strength, while the matrix protects them from damage and ensures that they are evenly distributed.

Other fibers, such as polymers and carbon fiber, have mechanical qualities that are roughly comparable to glass fiber. Although it is not as strong or rigid as carbon fiber, it is substantially less expensive and brittle when used in composites. As a result, glass fibers are employed as a reinforcing material in many polymer goods, resulting in the glass-reinforced plastic, commonly known as “fiberglass,” which is a very strong and comparatively lightweight fiber-reinforced composite material.

For a range of applications, fiberglass composites are a common alternative

Fiberglass and composites are excellent choices for curved shell structures. It’s the most common material used in boat hulls, small planes, architectural domes, and camper shells. Composites are also an excellent choice for covering and enclosing machinery and equipment. The designer can give the covers any form or contour he or she wants. They’re light, corrosion-resistant, have a class A quality, and are reasonably priced.

The covering can also be wide and intricate, allowing for the replacement of multiple discrete panels with a single cover. Consolidating parts lowers costs and makes assembly easier. Sheet metal has traditionally been used to create coverings and enclosures for machinery and equipment. Sheet metal is a material that several designers and engineers are familiar with, and it’s a suitable choice for simple, box-shaped covers. Fiberglass and composites are suitable materials if the covers require shape, such as a bevel or radius corners, or if the covers are large.

The machine’s cover sends a powerful message to the buyer about the machine’s quality and performance. A Corvette with a boxy sheet metal body would not have been a world-class sports car.

Also, one good Fiberglass application are swimming pools. Fiberglass swimming pools have many advantages over traditional concrete pools. They are easier to install, require less maintenance, and are more energy-efficient. Fiberglass pools also have a smoother surface, which makes them easier to clean and less likely to harbor bacteria.

Also Read: Types of False Ceilings

Leave a comment