What is Roofing Sheet?

Roofing sheets are a necessary element of a structure since they embrace the foremost crucial component, a roof. These roofing sheets guarantee that the roof structure stays solid and that protects against pollutants, weather conditions, dust, and, most importantly, that you just have an adequate roof on top of a house. Different factors affect once choosing a roofing sheet include lifespan, qualities, and therefore the influence it’s on your assets.

Roofing sheets are made from a range of materials, every with its own set of qualities and use on different types of roofs. Selecting the acceptable roof sheet depends upon the customer’s roof need of how long and how durable roofing the customer needs.

Totally different styles of roof sheets have their own set of benefits and disadvantages. every type caters to a unique set of requirements. The elements that form up your sturdy roof because of the materials that make up your roof. the amount of protection provided by your roof is ultimately determined by the artistic combination of various materials that job along to deliver the best results. Roofing sheets are essential for safeguarding your roof from harsh weather, whether it’s for your garage, shed, or another structure entirely.

Types of Roofing Sheets

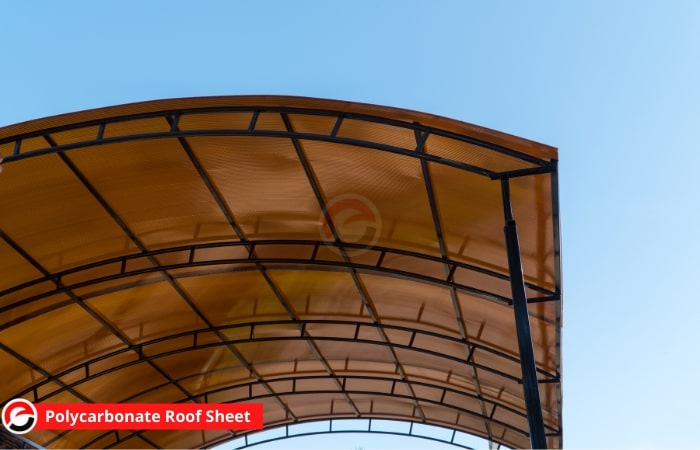

Polycarbonate Roofing Sheet

Polycarbonate is made up of polymers that are transparent, durable, heat resistant as it has a carbonate group in its molecular structure. They’re wide employed in industrial and outdoor café settings, commercial places as it has high insulation properties and very good UV ray protection. Polycarbonate roofing sheets, thanks to their transparency, are ideal for structures that need loads of light like gardens, swimming pools, patios, warehouses, etc.

These sheets are mainly used to enhance home and outdoor living spaces. Because these sheets are pH-neutral, they can withstand varying temperatures while remaining stable.

These sheets are available in a variety of panels, such as:

- Clear – allows for lighter and maybe the best roofing material during the hot summer months.

- Bronze- Underneath it, bronze emits an odd light.

- Opaque – allows very little light in and can be the best part of a roof during the hottest days. It also aids in UV ray protection.

Metal Roofing Sheet

Metal roofing sheets are a popular selection because of their glorious insulating properties. This sheet is composed of aluminium, copper, zinc, and in old times steel where also be used. Metal roofing is flexible to face up to virtually any variety of weather. Metal roofing is out there in a variety of colours and finishes, including the looks of natural cedar shakes or stone. it’s a lot of immune to fireplace and might withstand a storm while not being damaged. These sheets are used for sheds in gardens, home cladding, structures, garages, and industrial roofs.

Metal roofing sheets are environmentally friendly roofing solutions because they can be recycled. In terms of composition, metal roof sheets are kind of like corrugated roofing sheets, however, they need fewer curves. This class of roofing sheets comes in exceedingly kind of styles, textures, and colors, and you’ll choose from up-to-date and ancient styles for your home.

Advantages: They are simple to put in and maybe custom for building rooftops. They are durability, cost, energy efficiency, and longevity. Metal roofing panels can face up to extreme weather such as serious rains, snow, and even fire. they’re conjointly proof against pests and are most popular because of their longevity and durability. Metal roofs are glorious insulators and are usually utilized in garden structures, garages, backyards, house cladding, and industrial roofs.

GI Roofing Sheet

Galvanized iron (GI) sheets are steel sheets that are dipped in molten zin so that a layer of zinc is formed on the sheet to act as a protective layer on it. It reacts with the surroundings to defend the base metallic.

The GI coating has a completely unique metallurgic structure that shields in opposition to abrasion and mechanical damage all through transportation, erection, and service.

GI roofing sheets are useful in automatically shielding and can take damage and still last for long. The sheets guard any tiny location broken throughout transportation via way of means of supplying cathode or sacrificial protection. As a result, the coating protects the entire duration of the sheets.

Plastic Roofing Sheet

In most parts of the country, these sheets are the least desired various for roofing applications. as a result, of they’re less sturdy than alternative styles of roofing sheets, they are principally wont to cover garden sheds or temporary constructions.

The upper the value of the roofing sheet, the higher the standard of the plastic. This raises the value of plastic sheet installation. The cost of Plastic roofing sheets is commonly priced between Rs five hundred and Rs one thousand per sq. meter.

Fiberglass Roofing Sheet

Fiberglass profiles are a low-cost alternative to normal materials like concrete, steel, aluminium, and wood. in contrast to these materials, which solely have one basic strength, GRP has multiple advantages. As a result, covering material is ideal for future property building. it’s a similar high strength as steel however simply a fourth of the density.

It’s additionally possible to avoid wasting weight compared to aluminium as a result the density is 30% lower. they’re run-resistant to harsh chemicals, liquids, and alkalis. As a result, they are perfect for waste product treatment facilities, swimming pools, cooling towers, and buildings wherever corrosion may be a concern. These sheets are frequently used in fine arts roofing, skylights, clear acoustic barriers, coated walkways, and alternative applications.

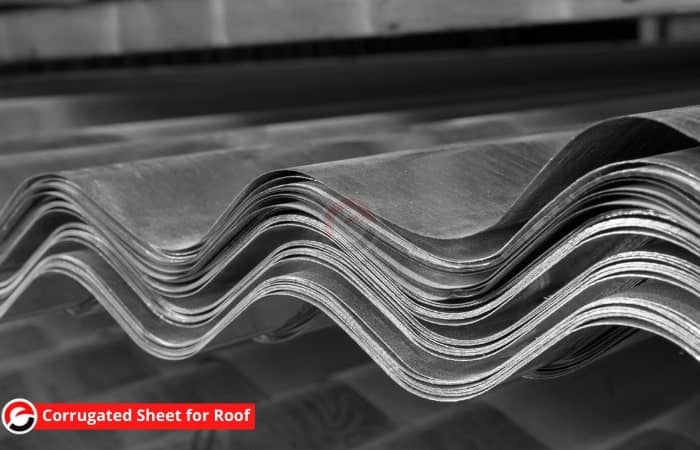

Corrugated Sheet for Roof

Corrugated roofing sheets, which are ordinarily used in agricultural structures, have continuation folds on their surface. they supply years of dependable quality and inflated strength because of their distinctive design. Their furrowed pattern with ridges and grooves strengthens them even over previously. The wavy structure permits for larger strength over smaller surface regions.

Attributable to the distinctive corrugated form, fragile and lightweight metals like aluminum may additionally face up to decades of weather abuse. corrugated sheets should be repaired each 5-10 years, depending on the pollution levels within the area wherever they’re put. These roofing sheets are completely sturdy and eco-friendly and are nice for shielding garages, porches, and sheds. In India, the cost of corrugated sheets price is in the range of Rs 250/square meter to Rs 500/square meter.

Galvanised Steel Sheets

Galvanized steel sheets serve as the inspiration for various corrugated sheets, similar to those coated with polyester paint or protected by PVC plastisol-coated roof sheets. Polyester painted sheets are normally utilized in agricultural constructions thanks to their medium-length life and economic effectiveness.

PVC Plastisol Coated Sheets

PVC Plastisol-coated corrugated sheets are very long-lasting. they’re the product of steel sheets that are ready and have PVC rolled on the prime of them. These roofing sheets aren’t without delay scraped or light and should normally endure for 25-30 years.

Polyester Painted Sheets

Polyester is applied on zinc-coated steel that has been primed. This type of roofing features a medium lifespan and will be serviceable between 5 to 10 years, or less typically if pollution is present. Polyester paint is additionally less costly than different roofing materials, comparable to PVC Plastisol coating.

Bitumen Sheets

Bituminous roof sheets are supposed to safeguard each residential and business structure. Layering that comes to the positioning within the style of rolls, because the name implies. These are then distributed out and placed on a stable platform. A bituminous waterproofing film is the most well-known type of sheet-based coating. using blowtorches, this kind of membrane attaches to the substrate with hot tar-based cement.

An identical hot adhesive is employed to create joints between near membranes. identical air cannon is additionally used to make joints between adjacent layers. to border a watertight junction, sheets are coated by 100mm. Some films are even linked by dissolving them with a hot compressed air gun so covering them with a previous layer.

Also Read: False Ceiling

Advantages of Roofing Sheets

- The most significant advantage of employing roofing sheets is that they may endure for up to 100 years since they do not corrode and are one of the most durable solutions available.

- Roofing sheets won’t decompose and cannot be attacked by insects like termites or the like.

- They are usually chemicals treated that inhibit alga development even throughout severe rainfall.

- a number of these roofing sheet materials also are fireplace resistant, which is another advantage that may save lives in the event of an accident.

- Because the sheets are lightweight, they are simple to install. In truth, corrugated sheets are a popular DIY activity, while in India, experts are employed for the task.

Disadvantages of Roofing Sheets

- Denting, bumping, and bruising are some of the standard concerns that are difficult to prevent while operating with Roofing sheets.

- Roofing sheets could be crumpled or broken as a result of hailstorms.

- The installation price is slightly greater; however, the cheap maintenance cost quite makes up for it within the long term.

Purpose of Roofing Sheets

The main Purpose of the roofing Sheet is to protect the interior of the house, yard, etc against pollutants, weather conditions, dust and keep it long-lasting to create a liveable place inside the structure.

Leave a comment