What is Non-Destructive Testing of Concrete?

For over four decades, non-destructive testing of concrete or non-destructive techniques has been in use. During this time, it has progressed to the point that it is currently regarded as a powerful tool for evaluating existing concrete structures in terms of strength and longevity, as well as for assessing and controlling the quality of hardened concrete. This approach may be used to investigate crack depth, microcracks, and gradual degradation in some situations.

Introduction to Non-destructive testing

- Though non-destructive testing procedures are very straightforward to use, analyzing and interpreting test findings is more difficult.

- As a result, analyzing the hardened characteristics of concrete necessitates specialized expertise. Because the specimen is not loaded to failure in non-destructive testing, the strength inferred or calculated cannot be anticipated to give absolute values of strength.

- As a result, these approaches seek to test certain additional characteristics of concrete in order to determine its strength, durability, and elastic parameters. Hardness, resistance to projectile penetration, rebound number, resonance frequency, and capacity to transmit ultrasonic pulse velocity are some of the characteristics of concrete.

- Concrete’s electrical characteristics, as well as its ability to absorb, scatter, and transmit X-rays and Gamma-rays, as well as its reaction to nuclear activation and acoustic emission, enable us to determine its moisture content, density, thickness, and cement content.

Also Read: Complete Guide on Grades of Concrete

Non-destructive testing methods of concrete?

Various non-destructive concrete testing procedures have been developed based on the above:

- Surface hardness test

- Rebound Test

- Penetration and Pull out technique

- Dynamic or vibration test

- Combined method

- Radioactive and nuclear method

- Magnetic and electrical method

- Acoustic emission technique

1. Surface Hardness Test

The Williams testing pistol and impact hammers are examples of indentation hammers that are exclusively used to estimate concrete strength.

Because concrete hardens as it ages, the hardness of the surface may be used to determine the concrete’s strength.

- The hardness of concrete surfaces is measured using a variety of procedures and equipment.

- Some of the instruments for evaluating surface hardness include the William testing pistol, Frank spring hammer, and Einbeck pendulum hammer.

2. Rebound Test

The elastic rebound of concrete is measured by the rebound hammer test, which is generally used for estimating concrete strength and comparative research.

Schmidt’s Rebound Hammer: Schmidt’s rebound hammer, which was invented in 1948, is one of the most widely used tools for determining surface hardness.

- It consists of a tubular casing with a spring control hammer that moves on a plunger.

- When the plunger is pressed on the concrete’s surface, the mass of the plunger bounces back. It retracts against the spring’s force.

- When the hammer strikes the concrete, the spring control mass springs back, dragging the rider down the guiding scale.

- The rider can be kept in place while the reading is taken by pressing a button. The rebound number is the distance traveled by the mass. The rider moves along a graded scale to signify it.

- The test can be done horizontally, vertically (upwards or forwards), or at any angle in between.

- For the same concrete, the rebound number will be different at each angle, necessitating a separate calibration or correction chart.

Also Read: Planning and Site Preparation for Concrete

3. Penetration and Pullout Technique

The usage of the Simbi hammer, Spit pins, the Windsor probe, and the pullout test is among them. These are used to estimate concrete strength and evaluate its penetration and pullout resistance. They may also be utilized for comparison research.

- A pullout test determines the force necessary to remove a specifically designed rod with an expanded end cast into concrete from the concrete.

- The more power is required to pull out the concrete, the stronger it is.

- Incorporating components into the structure would be the perfect method to use pullout tests in the field.

4. Dynamic or Vibration Test

Resonant frequency, mechanical sonic, and ultrasonic pulse velocity techniques are among them. These are used to assess concrete’s durability and homogeneity, as well as its strength and elastic characteristics.

- The fundamental resonant frequency of vibration of a specimen is determined using this approach.

- The point of greatest amplitude for the different driving frequencies generated indicates the resonance. The instrument used for this is commonly referred to as a “Sonometer.”

- The majority of resonant frequency techniques are employed in the laboratory.

5. Combined Method

The strength of concrete has been estimated using a combination of ultrasonic pulse velocity and rebound hammer.

- Estimating the compressive strength of concrete in a structure is one of the most significant goals of non-destructive concrete testing.

- Anyone’s approach may or may not produce accurate results. It has been discovered that using more than one approach at the same time produces trustworthy findings in terms of a structure’s strength.

- The ultrasonic pulse velocity method in conjunction with hardness measuring techniques, as well as the Rebound Hammer method, were determined to be the most preferred combination.

6. Radioactive and Nuclear Method

The X-ray and Gamma-ray penetration tests are used to determine the density and thickness of concrete. The neutron scattering and neutron activation techniques are also employed to determine moisture and cement content.

- It’s only recently that X-rays and gamma-rays have been used as a non-destructive approach for assessing concrete characteristics.

- Both X-rays and gamma-rays, which belong to the high-energy portion of the electromagnetic spectrum, penetrate concrete, but their intensity is reduced.

- The amount of attenuation is determined by the kind of substance, its thickness, and the wavelength of the light.

- The incoming gamma-ray intensity and the emerging gamma-ray intensity after passing through the specimens are both measured.

- The density of structural concrete members is calculated using these two numbers. The thickness of concrete slabs of known density has been measured using the gamma-ray transmission technique.

- A known-intensity gamma radiation source is used to pass through and permeate the concrete. The intensity on the other side of the face is measured. The thickness of the concrete is determined using this information.

7. Magnetic and Electrical Method

Magnetic methods are used to determine the cover of reinforcement in concrete, whereas electrical methods, such as microwave absorption techniques, are used to determine the moisture content and thickness of concrete.

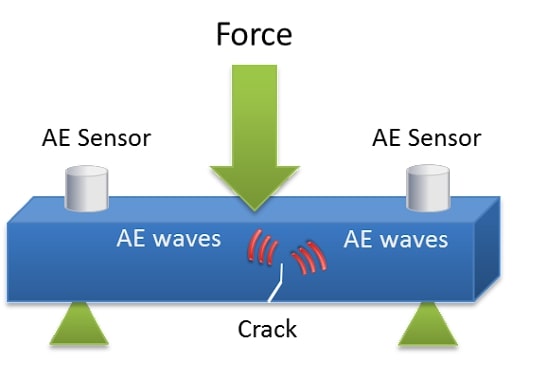

8. Acoustic Emission Technique

These have been used to investigate the beginning and progression of concrete fractures.

Comparison of Non-destructive Testing vs Destructive Testing

| Non-Destructive Testing | Destructive Testing |

| It’s a tool for detecting material flaws. | It’s used to figure out what the material’s characteristics are. |

| The materials are not subjected to any load. | The materials are subjected to a load. |

| There are no load applications, thus there is no risk of material damage. | The material is damaged as a result of the load application.

|

| In the majority of the tests, no additional equipment is required. | It is necessary to have specialized equipment. |

| Relatively less skill required. | Skill is required. |

Advantages of non-destructive testing of concrete?

- The equipment is simple to use.

- Defects can be found without causing damage to the components.

- The methods are rapid and precise.

- Electrical, magnetic, and chemical characteristics can be used to sort components.

- It’s simple to keep track of test results and other information.

Also Read: Light Weight Concrete

Disadvantages of non-destructive testing of concrete?

- Manual operations need the attention of skilled experts.

- Inspection of irregular components might be difficult.

- The couplant’s requirement

- Water-resistant test items are required.

Concrete Properties Assessed by NDTs

- Strength characteristics in situ

- Durability

- Density

- Moisture level

- Properties of elasticity

- The size of the visible fractures

- The thickness of structural components with only one exposed face.

- Steel reinforcement location and condition

- Over the reinforcement, there is a concrete cap.

- Even when concrete members are only accessible from a single surface, reliable assessment of their integrity or identification of flaws is possible.

Also Read: Revibration of Concrete

Leave a comment