We can also refer to the Bar Bending Schedule as the BBS. Bar Bending Schedule is the comprehensive list that signifies the category, extent, locale, imprint, size, number, and the bending of each bar or invention in the reinforcement diagram.

In other terms, we can also infer the bar bending schedule as the extensive list of all the reinforcement bars for the reinforced concrete undertaking of any structure. This thorough procedure of presenting the type, size, location, mark, length, number, and the bending facts of each bar in the reinforced concrete work is inferred as Scheduling.

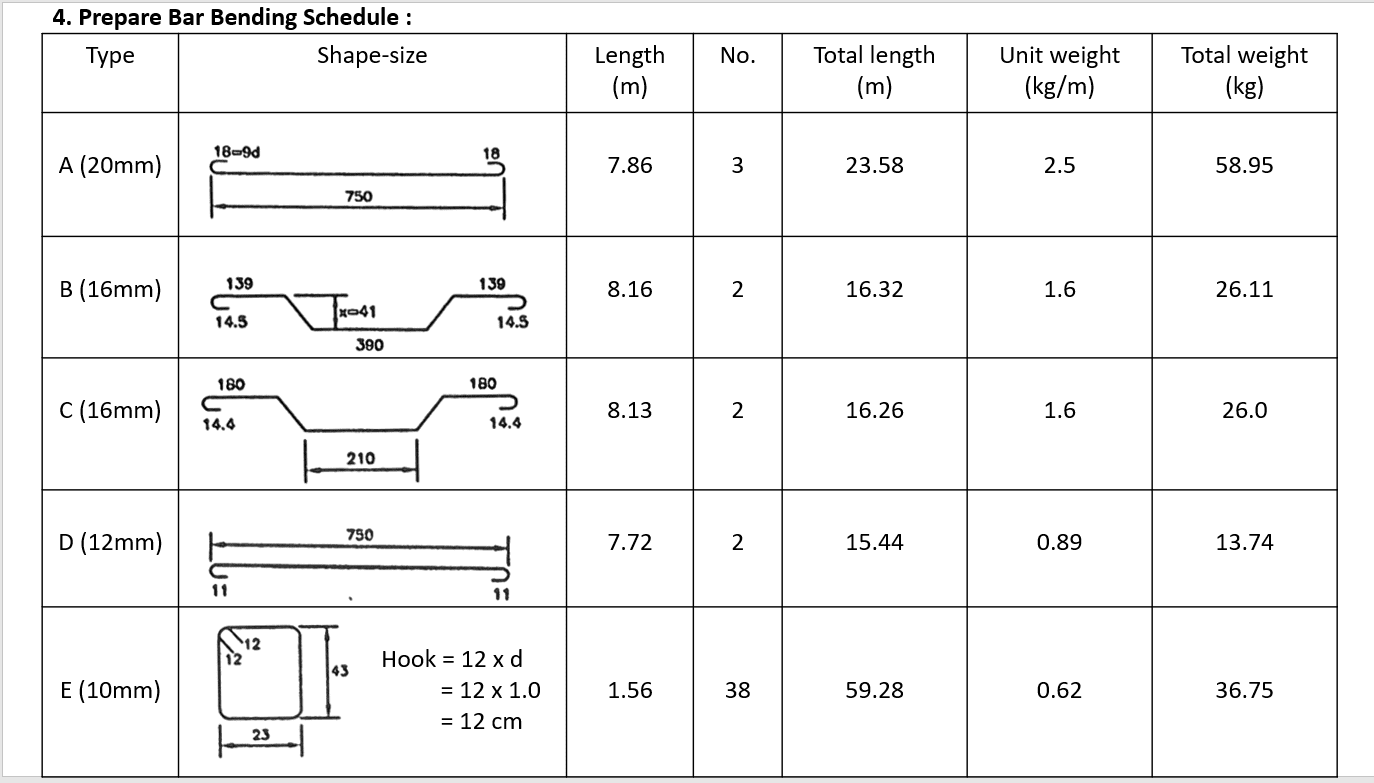

The main basis of practicing the bar bending schedule is to produce all the rebars efficiently in the structural component as well as to exhibit a thorough description of the reinforcements. It is largely depicted in tabular format.

Download: 30+ Bar Bending Schedule Advanced Spreadsheets (EXCEL)

Importance of Preparing Bar Bending Schedule

The main implications of preparing the bar bending schedule are as given below:

a. It is necessary for specifying the quantities of elements i.e. especially steel.

b. It presents all the facts of the rebars so that the wastage can be removed.

c. It is vital for the analysis of the cutting length of several categories of rebars.

d. It benefits the workmen and laborers in finishing off the reinforced concrete chores properly.

e. It functions for formulating the bills that can be conceded to the customers.

Persons Utilizing The Bar Bending Schedule

The following workers make usage of the made bar bending schedule are as follows:

a. The contractor who provides the order of the total number of reinforcements.

b. Fabricator who aids in fabricating the reinforcements.

c. Quantity Surveyor

d. Site Incharge

e. Detailer, and so on.

Also read: A Complete Guide on Concrete Slump Test for Workability

Details Exhibited By The Bar Bending Schedule

The bar bending schedule, in common, provides the ensuing details:

a. Designation of Member

b. Mark of each Bar

c. Diameter of each Bar

d. Length of each Bar

e. Bar Mark

f. Number of Members

g. Number of Members in each Bar

h. Total Number of Bars

i. Total Length

j. Shape Code

k. Bending Dimensions

How can you organize the Framework For The Preparation of Bar Bending Schedule?

a. The bars must regardless be summarized in the account of floors i.e., floor by floor for constructing structures.

b. Each structural unit must include a large number of bars formed together. For instance; beam, column, etc.

c. The fabrication list and the structure of bars must be prepared insubordination with BS 8666.

d. The lists for the cutting and bending objective must be delivered in a different A4 size paper and should not be encompassed in the comprehensive reinforcement illustrations.

e. The bar mark consideration on the label bound to a specific bundle of bars must considerably exemplify the unusual properties of that specific category only.

Also Read: Different Types of Estimates Calculated during the process of Construction

Stepwise Guidelines for the Preparation of Bar Bending Schedule.

First of all, you need to download a Bar Bending Schedule excel sheet by clicking on the link given below:

Download link: Bar Bending Schedule Xls

Step 1. Designation of Members (Steel Bars)

The kind of Steel bar or Member is usually labeled with a number or bar tag in the structural representation. Now, you need to open a structural representation and list down all the shapes of the bar you recognized in the structural representation. Now mark the diameter of the Member in the table.

RCC Drawing shows the number of bars like #5, #6, #9, etc, along with the Diameter of the Bar (e.g. #6Abhishek12”)

Step 2. Count the Number of bars

Now, you can calculate the number of each several shapes of the bar and write down in the bar bending schedule.

To estimate the number of bars in the big slab structure, you have to examine the specific spacing between bars (center to center or c/c) and the length of the concrete slab in which the bars are scattered.

Number of Bars = (Concrete slab length in which bar is Distributed – 2 X Cover) ÷ (c/c spacing between bars)

For Example:

Suppose, 10 MM bars are used in the 10 m long slab at 150 mm c/c spacing, Analyzing the side cover of 50 mm. Then compute the number of bars

Number of Bars = (10000 – 2 × 50) ÷ (150) = 66 Bars of 10 mm Día

Step 3: Compute the length of Reinforcement bars

The procedure, to compute the length of reinforcement bars are:

Length of Bar = Length of Concrete member (the direction in which bar is placed) – (2 × Cover) + Development length

Step 4: Compute the unit weight of Reinforcement Bar

The process for calculating the Unit weight of Bar is:

Unit weight of Bar = Volume of Bar X Density of Bar (7850 kg/m3)

Unit Weight of Reinforcement Bar with Diameter (D) = D2 / 162

Example, 10 mm Diameter reinforcement bar Weight = 102 /162 = 0.617 kg/m.

Step 4: The diameter enters the bar in mm Unit Weight in kg/m

- 8 = 0.395 kg/m

- 10 = 0.617 kg/m

- 12 = 0.889 kg/m

- 16 = 1.580 kg/m

- 20 = 2.469 kg/m

- 25 = 3.858 kg/m

- 32 = 6.321 kg/m

- 40 = 9.877 kg/m

Step 5: Compute the Weight of a specific Shape of Bar

Weight of Reinforcement Bar (Shape of Bar) = No of Bars X Length of Bars X Unit weight of Bar

Preparation Of Bar Bending Schedule

The essential section for the bar bending schedule can be documented as follows:

a. The structure of Bars

b. The diameter of Bars

c. Bar Reference

d. Spacing

e. Length of Bars

f. Cutting Length

g. Number of Bars

The accurate reinforcement representation delivers several knowledge expected for the bar bending schedule. Such details encompass the structure of bars, length of bars, the diameter of the bar, and the spacing of bars.

The formula for computing the various parameters are as follows:

a. Number of Bars

Number of Bars = (Length/ Spacing) + 1

b. Cutting Length

Cutting Length = True Length of Bar – Deductions

The aspects that must be considered during the process of the bar bending schedule are:

a. The bars should not be kept up greater than 36mm in size.

b. The process of welding should not be executed at the bends.

Also Read: Complete Guide on Grades of Concrete

Main Points To Keep in Mind For Bar Bending Schedule

1. Some of the normally used diameters of Reinforcement Bars (in mm) are as follows:

6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 28mm, 32mm, 36mm, and 40mm

2. The Standard Length of Reinforcement Bars (in m) is always taken as 12m.

Weight of Bar Per Length (in kg/m)

Weight/m = D²/ 160

For example; if the diameter of the reinforcement bar is 16mm, then,

Weight/m = 16²/ 160 = 1.6 kg/m

3. Weight Per Bar (in kg/bar)

The weight per bar can be portrayed as,

Weight/ bar = Weight of Bar perm x Standard Length of Bar

= 1.6 x 12

= 19.2 kg/bar

4. The diameter of Reinforcement Bars (in inches)

- #3 Rebar = 3/ 8 in = 9.525 mm

- #4 Rebar = 1/ 2 in = 12.70 mm

- #5 Rebar = 5/ 8 in = 15.875 mm

- #6 Rebar = 3/ 4 in = 19.05 mm

- #7 Rebar = 7/ 8 in = 22.225 mm

- #8 Rebar = 1 in = 25.4 mm

- #9 Rebar = 9/8 = 28.575 mm

5. Standard Length of Reinforcement Bar (in feet)

The standard length of the reinforcement bar is taken as 40 ft.

6. Weight of Reinforcement Bar per Length (in kg/ ft)

The weight per bar can be computed as,

Weight/ Length = D² / 533

For example; if the diameter of the reinforcement bar is #5 i.e. 5/8 in or 15.875 mm, then,

Weight/ Length= 15.875²/ 533 = 0.473 kg/ft (since, D must be in mm)

7. Weight of Reinforcement Bar per Bar (kg/ bar)

Weight/ Bar = (D²/ 533 )* standard length of bar

For example; if the diameter of the reinforcement bar is 15.857mm (#5), then,

Weight/ bar = (15.875²/ 533) * 40

= 18.92 kg/ bar

8. Cutting Length of Main Reinforcement Bar with Hook:

Length of Hook = 9d, where d is the diameter

Length of Main Bar = L + 9d + 9d

9. Cutting Length of Main Bar with Bend

Length of bend = 10d – 6d

Length of Main Bar = L + 12d + 12d

10. Overlapping

Neck Column to Footing Overlapping = 40d – 50d

Column to Column or Beam Overlapping = 50d

Development Length for Dowel Bars = 16d

General overlapping on Completion of 12m bar = 50d

11. Concrete Cover

Cover includes a clear cover and effective cover.

Clear cover for footing is always taken as 75mm, for column 25mm to 50mm, for beam 25 to 50mm and for slab 25mm.

12. Bend Deduction

For 45 degree bend = 1d

For 90 degree bend = 2d

For 135 degree bend = 3d

13. Crank Length & Extra Bar Length

For 45 degree bend, crank length = 0.42d

For 30 degree bend, crank length = 0.27d

For 60 degree bend, crank length = 0.58d

Length of extra bar = L/ 4

Frequently Asked Questions

What do you mean by development length?

A development length can be specified as the amount of reinforcement(bar) length required to be embedded or projected into the column to organize the desired bond strength between the concrete and steel.

Why is the lap provided?

A Lap is employed when two pieces of reinforcing bar (rebar) are placed side-by-side to generate a constant line of rebar. The length of the lap varies according to the concrete strength, the rebar grade, size, and spacing. The purpose of the lap is to transfer load from one bar to another bar as well as retain continuity.

What are the formulas of cutting length in BBS?

Cutting Length = Clear Span of Slab + (2 × Development Length)+(2 x inclined length) – (45° bend x 4) – (90° bend x 2)

Cutting Length = Clear Span of Slab + (2 X Ld) +(2 x 0.42D) – (1d x 4) – (2d x 2) [BBS Shape Codes]

Conclusion

We discussed how to prepare bar bending schedules along with some terminology like development length, cutting length, lapping, etc. We tried to provide all the basic information related to the bar bending schedule. Read the full blog post to know all the important points related to this topic.

Also Read: Planning And Site Preparation For Concrete

Leave a comment