Glass wool has become a popular material for the construction of buildings. People around the world are looking for eco-friendly construction materials. Also, the ecosystem of our planet is affected by global warming and waste buildup. As a result, the idea of green building developed.

Here, Glass wool is proved a green-building material. Its composition makes it superior among all construction materials. So, keep reading to discover its properties, production process, and applications.

What Is Glass Wool?

Glass wool is an inorganic substance. It converts molten glass into cotton by melting it. It has an excellent composition and excellent characteristics. It is an eco-friendly material that plays the best role in green building.

It is made up of silica sand, recycled glass, and fixing agents. These materials work perfectly together. This is the reason; it provides exceptional insulation and covering to houses.

Also Read: MDF vs Particle board

Glass Wool Composition

Glass wool is made up of the following materials:

- Sand

- Limestone

- Soda ash

- High percentage of recycled glass

- Minerals

- Other raw materials

Properties Of Glass Wool

The key properties of glass wool are mentioned below:

- This material is among the greatest substitutes for the insulation used in homes.

- Glass wool is an environment-friendly material. That’s why; it is entirely natural mineral wool used in construction.

- It has a high percentage of recycled material. So, it is an inexpensive and cost-effective product.

- It has good tensile strength. In this way, it can absorb incident sound. Also, it is used as an acoustic barrier to reduce sound transmission.

Glass Wool Density

The density of glass wool is about 12 Kg/M3 – 48 Kg/M3. This eco-friendly material has standard thicknesses of 25 mm and 50 mm.

Advantages of Glass Wool

The pros of using this green building material are the following:

- Excellent qualities of glass wool include acoustic and heat insulation.

- It is a cheaper and more affordable material. It has low cost than other insulators on the market.

- It is made of fire-resistant material. So, it can withstand flames up to 300 degrees Celsius.

- It is readily available along with other repair supplies in every DIY store.

- This material is designed to be rot-proof. It can last a very long time.

- It poses no health risk to the people living in the house.

- It is also highly resistant to rats and other pests.

- Glass wool is produced as a perfect insulator for attics and cellars. It also protects outdoor shelters.

- It may insulate all different types of surfaces. It is including inhabited roof spaces, walls, partitions, etc.

- This material has an elastic and adaptable character in nature. So, its installation is very simple. It can fit on floor, roof, and wall spaces.

Disadvantages Of Glass Wool

Cons of glass wool are listed below,

- Glass Wool cannot be installed without gloves, glasses, and protective clothes. If you don’t take preventative precautions, it causes skin and eye irritation.

- This material has a sensitivity to moisture. Thus, it should only be used in dry environments.

- It is sensitive to water. Also, if your home is subjected to these conditions, it may need to be updated.

- The raw resources of wool glass material are non-renewable. This is the reason, sometimes it has a bad ecological balance.

- Glass Wool has sound resistance properties. So, it has a restricted value.

Applications of Glass Wool Insulation

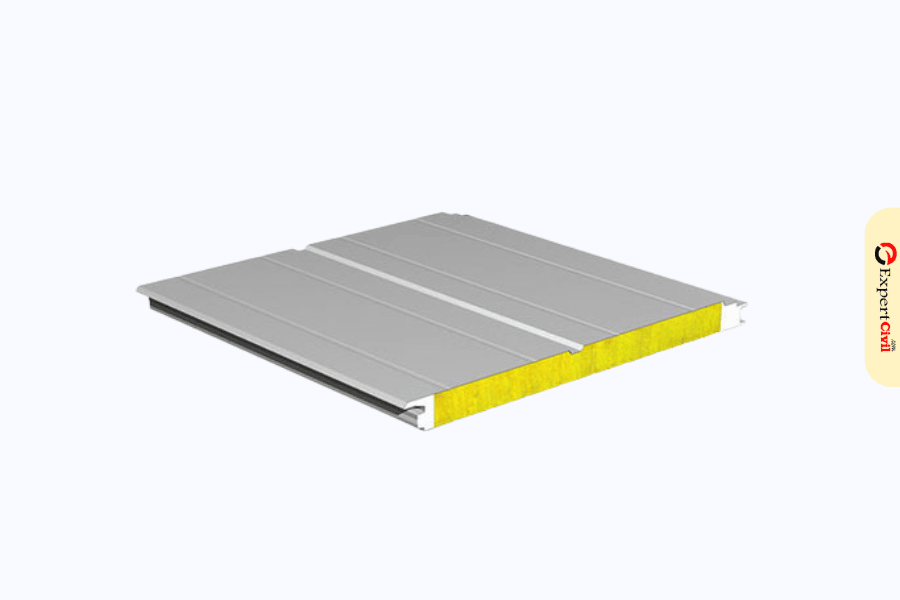

Roof

Nearly 40% of the heat gain or loss in a building occurs through the roof. In return, it needs more electrical appliances for use. And it ultimately encourages energy waste. That’s why; using sandwich glass wool material is the best option for saving energy.

It helps to increase a building’s energy efficiency through the insulating material. Glass wool insulation preserves the building envelope. It is allowing heat to escape during the summer. It also provides comfort and reduces energy use.

Also Read: 25 Different Parts of Roof

Ceiling/ Soffit

Glass wool in the ceiling and soffit offers several benefits. The most valuable benefit among others is thermal comfort. It provides insulation for the ceiling or soffit.

Glass wool installation in the ceiling can also help to reduce noise. It can control noise entering through roofs from another story.

Partition Wall

Glass Wool is often used in partition walls of household and industrial structures. It can absorb sound from the environment. Simple brick have can be replaced with this material. It has higher fire and acoustic resistant qualities with less wall thickness.

Glass Wool can reduce noise by up to 60 dB or more. Also, it is maintaining fire safety requirements in partition walls. Modern partition walls used in business buildings should serve a very useful purpose. It is important to install materials like glass wool for meeting the necessary specifications.

Floor

Insulating the floor is necessary to prevent impact noise. Glass wool applies on the floor when it separates two different floors. Glass wool insulation can be used in situations to isolate noise. It reduces the noise coming from machinery or appliance. It also insulates noise coming from humans walking on the floor.

Glass Wool has a strong compressive capacity. It can withstand shock loads brought on by a variety of disturbances. Glass wool does not transfer sound to other areas of the building. So, this material plays an important role in its layer for floor insulation.

Industrial Insulation

Industries always need a sophisticated and extensive range of industrial insulating materials. Among all other materials, glass wool proves an excellent item for industries. Glass wool provides businesses with high-quality insulating materials. It has a range of applications and temperatures. They are flexible to mechanical resistance and very compressible.

Good insulation material is needed in settings for safety and security. This material increases the sustainability of operations and processes. It has incredible heat resistance properties. In industries, glass wool could be combined with stone wool and ultimate mineral wool. It is used for a higher level of insulation. Also, it makes an effective and has a thinner profile.

Metallic Building

Metallic buildings take benefit from reducing the structure non-combustible. Glass wool resists water content from the building. It helps to make the structure durable and stable through its excellent properties. Glass wool can act as a heat-transfer barrier. It helps in keeping out summer heat and preserving warm air in the winter.

Automotive Insulation

Glass wool is created and examined under the quality requirement. That’s why; it can offer high thermal and acoustic performance. It has mechanical durability and fire safety. It maintains the precise temperature to maximize engine performance. It also reduces CO2 emissions to the environment. So, it can prove to be a powerful barrier against heat loss in automobiles.

Glass wool is an excellent product for molding. It allows for the use of processes like compression molding. As a result, one can make components in any shape with a variety of finishes. It is an advantage for usage in the automotive industry.

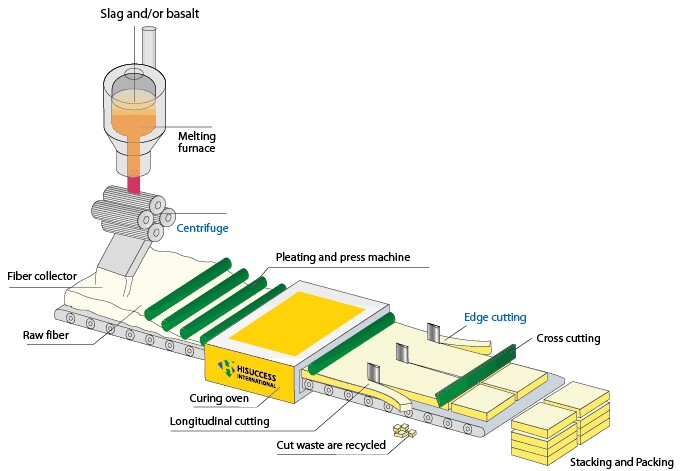

Glass Wool Production Process

Glass wool is made up of different materials with a specific production process. The whole process is explained below:

1. Batch

Sand, soda ash, limestone, and recycled glass are the key components of glass wool. These materials are kept in silos.

Then, all ingredients are weighed and combined. All materials are poured into a furnace to begin the process.

2. Melting

The combined components are completely melted. They are melted at a high temperature of more than 1,400°C. These materials are melted in an electric gas furnace.

3. Fiberizing

The liquid glass obtained from the furnace is then sent by a feeder to a fiberizing device. It is spun at a high speed through microscopic holes to form the fibers. After being formed into a blanket, these fibers are coated with a binder.

4. Forming

A curing oven is used to compress the fiber blanket to the required thickness.

5. Cutting

The blanket is then cut to the necessary width. Afterwards, it attains the desired thickness. To reduce waste, cutting off-cuts are finally recycled.

6. Packing

The mats are rolled before packing with the aid of a rolling machine. For the boards, a stacking machine is offered.

7. Palletization

For palletization, glass wool can be crushed up to 10 times its volume. A single pallet could hold all 36 of the glass rolls. These rolls were obtained during the operation.

What is Rock Wool?

Rock wool is a completely water-resistant material and has a higher specific weight as compared to glass wool. Rock wool can withstand about 600 degrees of high temperature. It is often used to insulate high-temperature thermal pipes from heat. Rock wool is less cheap and adaptable.

Glass wool Vs. Rock wool

The major difference between Glass wool and Rock wool are as follows:

| Glass Wool | Rock Wool |

| 1. It allows water penetration at a very low density. | 1. It is a completely water-resistant material. |

| 2. Glass wool can withstand temperatures of up to 260 degrees. | 2. Rock wool can withstand about 600 degrees of high temperature. |

| 3. Compared to rock wool, glass wool has a lower specific weight. | 3. Rock wool has a higher specific weight as compared to glass wool. |

| 4. It is often used for low-temperature pipeline insulation or general building insulation. | 4. It is often used to insulate high-temperature thermal pipes from heat. |

| 5. Glasswool is more adaptable and reasonable. | 5. Rock wool is less cheap and adaptable. |

Frequently Asked Questions

What Is Glass Wool Used For?

Glass wool is used for the following purposes:

1. Industrial and automotive insulation

2. Moisture and fire-resistant material

3. As a partition for Walls

A. Roofs

B. Ceilings

C. Floors

D. Metallic buildings.

Why Glass Wool Is A Good Insulator?

At first, Glass is melted and then spun into fibers in a centrifugal machine. After sedimentation and curing, it is cut into specified forms for various uses. A type of wool product has microscopic internal air pores.

These internal pores act as glass wool insulation. The air pores created a natural air layer. These pores improve the glass’s ability to insulate heat. As a result, glass wool insulation is the best material for thermal insulation.

Why Is Glass Wool Soaked In Water?

To produce a steam layer, glass wool is used. At the base of the boiling tube, there is a lump of water-soaked glass wool.

The water causes steam to be produced when heated. In this whole process, glass wool doesn’t take part in this reaction itself.

Conclusion

This article gives you complete detail on glass wool. To answer your questions, each application and its attributes are covered in detail. I hope this read provided you with enough information.

Also Read: Plyboard vs Plywood – Difference between Plywood and Blockboard

Leave a comment