What is a Flush Door?

- Flush doors feature plain facings on both sides and are a basic door style. They may be both indoors and outside.

- They’re commonly employed in situations when space is limited, and they’re more practical than stylish, but like with everything, a little ingenuity goes a long way.

- They might be kept intentionally basic in appearance to draw attention to other adjacent elements.

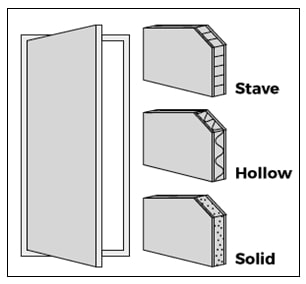

- The core of flush doors might be solid, hollow, or stave. If the core is solid, low-density particle board or foam is frequently used to entirely cover the area within the door, and it may be reinforced on either side with a form of laminate or plywood.

- They’re great for outside doors since they add insulation and robustness.

- Wooden slats piled on top of one another form the core of a flush door with a stave core.

- Some support may be incorporated into the frame if the core is hollow.

- They have a simple design. The hardware will be recessed if the doors are to be set on tracks so that they may move past one another. A closet might benefit from this sort of design.

Flush Door Definition / Meaning

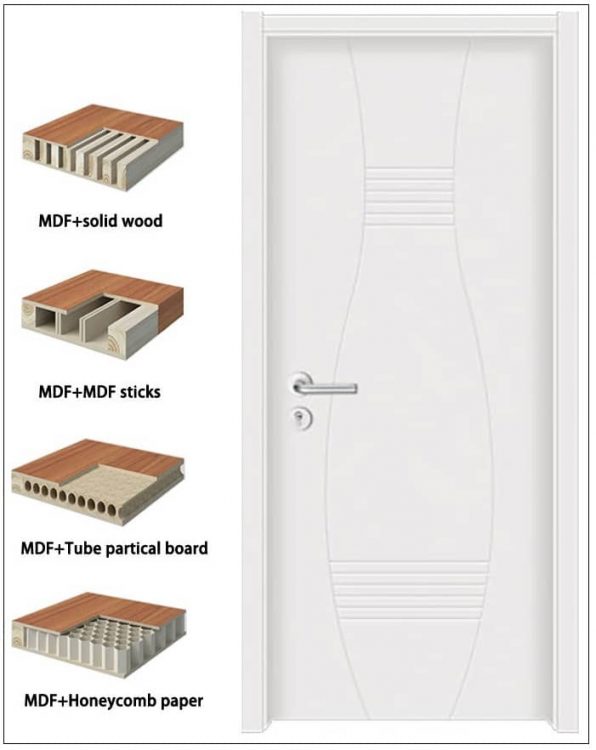

A flush door is a flat door that is not split into panels or mouldings and has a smooth surface. It is made out of a wooden structure that is coated on both sides with ply, MDF Board, or natural wood.

They feature flat surfaces on both sides and hollow interior parts that are filled with an infill material such as cardboard. The Flush door is then painted, veneered, or laminated in a variety of colours and patterns.

Flush Door HSN Codes

HSN Code 44182010

Under the Goods and Service Tax categorization, HSN Code 44182010 is used for flush doors.

| 44 | chapter number | Wood and Articles of wood; wood charcoal. |

| 18 | heading number | Builders’ Joinery And Carpentry Of Wood, Including Cellular Wood Panels, Assembled Flooring Panels, Shingles And Shakes |

| 20 | product code | Doors and their frames and thresholds |

| 21 | classification | Flush Doors. |

HSN Code 44182020

Under the Goods and Service Tax categorization, HSN Code 44182020 is used for flush doors.

| 44 | chapter number | Wood and Articles of wood; wood charcoal. |

| 18 | heading number | Builders’ Joinery And Carpentry Of Wood, Including Cellular Wood Panels, Assembled Flooring Panels, Shingles And Shakes. |

| 20 | product code | Doors and their frames and thresholds. |

| 20 | classification | Frames And Threshold Of Flush Doors. |

Also Read: All you need to know about Emulsion Paints

What are Panel Doors?

Traditional wood joiners such as rails, stiles, and infill panels are used to construct panel doors. They’re made from a variety of woods and come in a variety of colours. They’ve been in the construction industry for a long time and have a long history.

In the construction industry, panel doors have long been favoured.

What are Wooden Doors?

A wooden door is a hinged or otherwise movable barrier that allows people to enter and exit an enclosed space. A doorway or gateway is the constructed opening in the wall.

The basic function of a door is to offer security by restricting access to the doorway.

Difference Between Flush Door & Panel Door

| Flush Door | Panel Door |

| Flush doors are made up of a hardwood framework that is filled with solid core material and has a plywood top. To match the interiors, they are finished with laminate, paint, or veneer. | Traditional wood joiners such as stiles, rails, and infills are used to make panel doors. |

| The cost of flush doors is lower. | The cost of panel doors is higher. |

| Flush Doors are excellent sound insulators. | Panel Doors are poor sound insulators. |

| Flush doors have the potential to be fire-resistant. | Panel doors have a higher risk of catching fire. |

| Cleaning and maintaining flush doors are much easier. | Cleaning and maintaining panel doors is hard. |

Advantages of Flush Doors

- Flush doors can be utilised on the outside as well as the inside of a home. In today’s commercial and residential constructions, flush doors are commonly employed.

- Flush Door has a smooth and uniform surface.

- This style of door has clear lines, but no elaborate carvings. As a result, the designs are limited.

- In comparison to other doors, they are less expensive.

- Plain shutters with few seams are used on flush doors, making maintenance easier.

- Various finishes, such as laminate, paint, and veneer, are available for the doors. Even after many years, they barely break, crack, or peel.

- Sound travels well through flush doors.

- Termite attack is not a problem for them.

- It resists scratches and stains thanks to its non-porous surface.

- They’re sturdy, but they’re not particularly attractive.

Disadvantages of Flush Doors

- Because the flush door is built in a factory, the exact or precise size of the door opening must be specified, as changes are difficult to make later.

- Flush doors with a plywood covering cannot be utilised in areas where they will be exposed to rain and sunlight.

- The most significant downside is its weight. As a result, handling and transporting it to your home is tough.

- They are difficult to fix after the top veneer, laminate, or plywood begins to delaminate due to temperature, moisture, and other factors.

- Plywood-covered flush doors are not ideal for locations that are frequently exposed to rain and sunlight.

Types of Flush Doors

There are three types of flush doors:

- Solid Core Flush Doors

- Hollow Core Flush Doors

- Cellular Core Flush Doors

What is a Solid Core Flush Door?

- Flush doors with a solid core are highly popular. The hard and mineral character of the wood utilised in these doors is predominant.

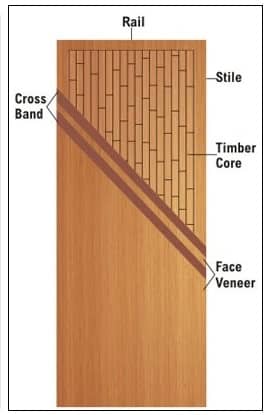

- These doors are made from various materials such as particleboard, laminated core, cross band, face wood veneer, blockboard, and so on.

- Solid-core flush doors cost between Rs. 220-250 per square foot in today’s market, depending on the grade of laminated materials.

- These doors must have stiles, top and bottom rails, and a width of more than 7.5 cm. This style of the door also has sound-deadening qualities.

- The frame of these doors is composed of timber wood, and hardwood lipping is applied to the framework to increase the door’s strength and longevity.

- The breadth of the wood lipping should be the same as the core thickness. They weigh a lot and have a lot of strength. These doors are mostly utilised as external doors for homes and other properties due to their high strength and stability.

Pros of Solid Core Flush Door

- Environmental changes have no effect on solid-core flush doors.

- These doors are environmentally friendly, waterproof, and sound insulators.

- These doors are stable and dimensionally precise.

- These doors are more sturdy and can hold a lot of screws.

- These doors are simple to clean and require little upkeep.

- These doors are of the highest quality, so they will endure a long time.

Cons of Solid Core Flush Door

- More Difficult to Install Due to Weight

- Hard to Repair.

- Limited Style Options

Also Read: What is Timber in Construction

What is a Hollow Core Flush Door?

- Hollow-core flush doors are hollow on the inside and have a supporting structure, which is primarily honeycomb.

- The stiles, top, bottom, and intermediate rails should all be at least 7.5cm wide, just like the solid core flush door. Stiles, top, intermediate, and bottom rails, as well as wooden battens fixed to the rails to cover spaces/gaps between stiles and rails, make up the frame.

- The plywood thickness of this door should always be greater than 6 mm. Under pressure, plywood sheets and face veneers are bonded to the core. These doors are less in weight than other varieties, however, they are not as robust as solid core flush doors.

- Hollow-core flush doors cost between Rs. 180 and 200 per square foot on the market.

Pros of Hollow Core Flush Door

- Hollow-core flush doors are lightweight, making them simple to handle and install.

- This door’s surface is stain, scratch, and crash-resistant.

- These doors are simple to install and may be manufactured in any shape.

- There are many different designs and decorative finishes available for these doors.

- It’s simple to make and inexpensive.

Cons of Hollow Core Flush Door

- Not Very Durable

- Don’t Insulate Sound or Reduce Noise

- Lower quality feel than Solid Core Doors

- Hard to Repair.

What is a Cellular Core Flush Door?

- The cellular core flush door frames are made up of plywood battens that are at least 25mm wide and are fixed together.

- The shutter is made by applying pressure on plywood sheets and facing veneers on both sides of the core. The plywood sheet thickness in this sort of door must always be greater than 3mm.

- These doors are heat and water-resistant because they have been chemically treated and vacuum pressed.

- A cellular core flush door costs between Rs.150 and 170 per square foot.

Pros of Cellular Core Flush Door

- For the convenience of installation, cellular core flush doors have a lockable space on both sides.

- These doors allow homeowners to modify their doors according to their needs and preferences.

- These doors have a lovely, warm, and historic look to them.

- This door necessitates less upkeep.

Cons of Cellular Core Flush Door

- Because flush doors are made in a factory, you must supply the exact size of the door; otherwise, it will be difficult to redo the size.

Comparison between Wooden & Flush Door on Various Parameters

| Factor | Flush Door | Wooden Door |

| Raw material Used | On both sides of the door, plywood, MDF, or a similar board is used to cover the timber frame. Typically, cardboard or board is used to fill the void inside the door. These doors are then finished with veneer or teak ply to give them a finished look. | Comprises a framing made of lumber sawn in the direction of the grain to the required length, breadth, and thickness. The interior sides of the frame are grooved to take one or more panels, depending on the demand or design. Panels can be made of wood or other materials. |

| Cleaning & Maintenance Required | Due to their simple look, flush doors are easy to clean since dust does not accumulate on their surface. A veneer skin is applied to the doors, and polish is applied to the doors. If the doors are painted, cleaning is as simple as using a dry towel. | In comparison to flush shutters, wooden shutters require more time and money to maintain since they have more grooves and patterns that gather dust and need periodic cleaning. |

| Thickness of Shutters | Flush shutters are typically 25mm, 30mm, or 35mm thick. Other door thicknesses may be available from some vendors. | In most situations, the thickness of a wooden panel door shutter is 30 mm, 35 mm, or 40 mm, but in rare cases, the thickness may be extended to 45 mm, 50 mm, or any other desired number owing to opening size, security, or design reasons. |

| Finishing | Paint is used to finish flush door shutters. If a polish finish is required on flush doors, teak face ply or veneer is attached to the face of the shutter, creating a teak face polish surface. | Wooden shutters can be polished with a variety of materials, including oil, paint, wax polishing, varnish, and spirit polishing, all of which are applied directly to the wood. |

| Advantages | They have a simple design and are less costly. | Wooden doors may be cut and changed to the appropriate size on the spot, and small adjustments can also be made. |

| Disadvantages | Because flush doors are made in a factory, the precise size should be supplied before the door is built; otherwise, it would be very difficult to redo the size. | Termites are more likely to attack wooden doors than other types of modern materials on the market today. |

| Strength | Because of their uniform construction, flush shutters are more durable. | Flush doors are less durable than wooden doors. |

| Aesthetical Appearance | Flush doors are less expensive, but they lack the visual appeal of wood doors. | Wooden doors are more appealing to the eye than flush doors. |

Latest Flush door design images

Here are some trending design ideas for flush doors (source)

Also Read: 11 Steps in Construction of Multi Storey Buildings

Frequently Asked Questions (FAQ)

-

Which flush door is best?

solid core flush doors because they have solid blocks of wood inside. Solid core doors are strong and have better soundproofing properties.

-

What is a flush door made of?

It has a wooden structure that is coated along both surfaces with ply, MDF Board, as well as natural wood.

-

What are flush doors used for?

Only the entrance opening and cupboards can be covered with flush shutters on the inside of the structure. These are not suited for use in toilets since they are treated with a water-resistant veneer. If the shutter is to be used in a bathroom, it should be lined with water-resistant ply or aluminium sheet.

-

Is a flush door good for a bathroom?

Yes. Flush doors have an unique coating that protects them from damage caused by severe heat or cold, and they are the most common bathroom doors.

-

Is flush door waterproof?

Yes. The majority of house entry doors are watertight flush doors. These doors are watertight to a high standard. It has a beautiful design, a nice pattern, and a shiny finish.

-

Flush door thickness?

The thickness of flush doors varies from 25mm, 30mm, 32mm, 35mm, 38mm, 40mm, 42mm, 45mm.

[…] it comes to choosing the perfect closet door or flush doors, there are many options available. The type of door you select can impact the functionality and […]