Curious to know about Mud Flooring? The flooring process is one of the most important steps in finishing the house. Nowadays, fine flooring is in demand for construction projects. We have already discussed different types of flooring in construction. But this article will only focus on mud flooring or earthen flooring.

Mud Flooring

If you are interested to know about mud floors, then you are at the right place. In this article, you can explore its characteristics, materials, and many more. So, give it a read to discover details related to mud floorings. Let’s start.

What is Mud Flooring?

It is a type of floor that is mainly made of mud. In ancient times, people always prefer mud houses. After that, they used bamboo for its structure. But their floors are still made of mud. The mud floors have the following features:

- Most affordable flooring option.

- Easy to construct.

- Simple to maintain.

Characteristics of Mud Flooring

Now, there are discussing a few of the basic characteristics of (mud) earthen flooring. As mud is the major material used in its construction. Here, characteristics are listed below:

1. Natural Insulation

- Mud floors have very natural insulating properties. It allows them to maintain a constant temperature. So, it can maintain warm air in the winter and cool in the summer.

- The mud house has the best ventilation system due to its porous structure. Yet, it’s sunny outside, but the inside temperature would be mild!

- The home is ventilated due to these pores. These pores allow proper air passage from the house. So, it controls the temperature of the house.

2. Recyclability

- In the current situation, environmental preservation is in full swing. Mud houses are a good contribution to our atmosphere. It can stop global warming. Mud replaces nonreusable material and helps in decreasing carbon emissions.

- After breaking down houses, the mud can be reused. Then, it becomes a part of compostable material.

3. Biodegradability

- Mud is a completely eco-friendly material. It lightens the stress on the world.

- The construction sector makes major use of such materials. Due to its disposable nature, it is the best option for industries. It eventually decreases their cost by fast-decaying ability.

4. Carbon Foot Printing

- Recently, it is a key component of construction projects.

- Cement emits carbon percentage. That’s why cement is replaced by mud.

- Mud reduces carbon fumes.

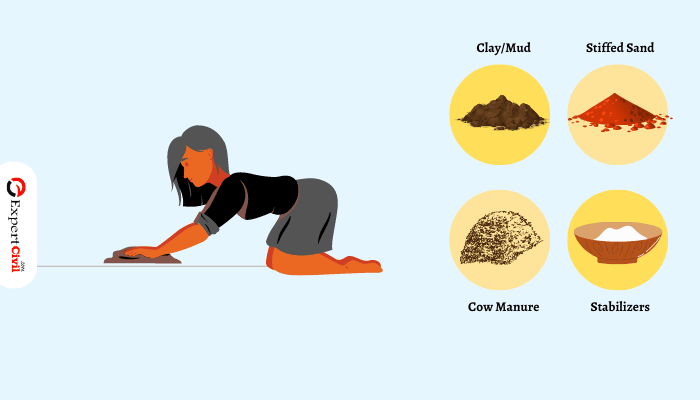

Mud Flooring Materials

The basic materials used in the construction of mud floors purposes are the following:

- Clay/Mud: It serves as the main component of mud floors. For example, murram, red soil, or yellow soil. To get the desired floor quality, the soil is crushed properly.

- Stiffed sand: It usually gives strength to mud. It also resembles cement aggregates.

- Cow manure: It serves in the construction of the mud floor. The availability of manure makes an option for its usage in flooring.

- Straw: Chopped and sifted straw is added to stop floor cracking. Paddy straw is a common material.

- Stabilizers: Stabilizers are added to clay to change its properties. It boosts the mud flooring’s tensile and shears strength. It also lessens the factor of shrinkage.

The most common stabilizers used for construction are:

- Cement

- Straw

- Plant juices

- Molasses

- Animal urine

- Oil, etc

- Cow dung

Mud Flooring Materials

The procedure of Mud Flooring

1. Choice of Materials

According to the project’s nature selection of materials is performed. The major materials include mud. The mud is used for the neat and strong flooring. It can withstand tensile and shear loads.

The mud needs to be fine-grained. It is free of coarse sand or even gravel. The mud is soaked in water before setting the floor. The soaking process is completed in 7 days.

2. Preparation of Bed

In the second step, fill the floor with water to wet it properly. First, adds a layer of hardcore stone or rubble layer. It has thicknesses from 15 to 25 centimeters. This stoned layer makes the durable floor. It helps to stop moisture. It does not allow rodents to make holes in the floor. The major issue of subterranean settling also reduces.

3. Making Materials Stable

Nowadays, building a mud house needs a proper construction process. The materials are stabilized by adding stabilizers. These stabilizers help to give a fine look to a mud floor. The insertion of stabilizers improves the quality of mud.

For example, Stabilized Compressed interlocking Earth Blocks (SCEB). It is a local mud that has a 5% cement addition. The completed product is compressed. It makes its material stabilize. Thus, it gives structural strength and water resistance.

4. Mixing Of Material

The chopped and sifted straw is added to the mud with the addition of water. Mix it, to make a consistent mixture of mud. After drying, straws stop the surface from cracking.

5. Applying Mud Paste

The previously mixed mud paste is applied to the prepared bed. The layer’s thickness is 10- 25 cm. It is best to spread the material in a single and uninterrupted layer.

6. Leveling the Surface

After spreading the mud paste, the surface is levelled by compacting. The paste helps to compact the surface. There is no addition of water in this step.

Wooden instruments are used for this process. The thickness of the compacted material is 6 inches. The tool marks must be eliminated while filling. The extra mixture is removed from the elevated portion.

7. Finalizing the Surface

A finishing coat is added on top of a tiled floor. It is also known as cow dung wash. The finishing coat is a mixture of cow dung and clay.

Mud flooring – Finalizing the Surface

It is applied in a thin layer on the compact floor. Specific patterns may also develop on the mud surface. This step is optional. Most people skip this task as an option.

8. Curing the Surface

This is the last step of mud flooring. Water is sprayed on the top of the floor. It can stop the fast drying of the floor.

Water spray maintains moisture distribution across the surface. Its interval may be regular. The floor is likely to break if this process is skipped.

Maintenance of Mud Flooring

Mud floors do not retain their fine look after 1-2 weeks. So, they usually need preservation. For its better condition, the mud floor can be maintained by keeping the following steps:

- Maintenance is the basic need for the mud floor to retain good condition. The floor should receive a thin cow dung wash. It causes the finished look of the floor. It can be done once a time in a week.

- Due to the application of a finishing coat on the floor, the floor is considered unclean. It happens sometimes.

Advantages of mud flooring

The major pros of mud flooring are as follows:

- It is eco-friendly flooring.

- This type of floor is cost-effective.

- Simple manpower can construct mud floors.

- Materials for mud flooring are easily available.

- It has resistance to fire.

- It is simple to maintain.

- This flooring can withstand extremely acidic environmental conditions.

- There is an availability of heat insulation properties in mud floors.

Disadvantages of mud flooring

The cons of mud flooring are as follows:

- It can easily absorb moisture from the environment.

- Its life span is short.

- It needs proper maintenance.

- It is less water-resistant.

- The mud floor is not durable.

Mud flooring vs PVC flooring

| Mud flooring | PVC flooring |

| 1. It is considered an affordable material. | 1. It is expensive compared to mud floors. |

| 2. There is no health issue related to mud floors. | 2. PVC flooring causes health issues due to the high emission of VOC. |

| 3. Mud floors can control temperature. | 3. PVC floors can’t adjust with temperature. |

| 4. it is a fire-resistant floor. | 4. PVC floor is not a fire-resistant floor as compared to mud floor. |

| 5. Unprofessional labor can construct this floor. | 5. Skilled labor is required to construct the PVC floor. |

Interesting Facts about Mud Floor

India is the second largest city in the world by population. There are around 118 million houses in Indians. According to a survey, around 65 million of them are still made of mud. In this era, it is so astonishing that 50% of homes still have mud floors. People are living in non-concrete houses.

While the reality is that this ratio is a result of poverty. Some peoples still suggest mud flooring. Because they evolved to alternative durable options for flooring. Yet, it hasn’t gained any traction.

Also Read: How To Buy Kitchen flooring – Complete Guide

Modifications to Flooring Made From Mud

Every improvement begins with fixing flaws in the current system. It also brings by enhancing it with new features. So, the modifications are discussed below:

1. Murram Flooring

Any kind of fragmented rock is called murram. Murram flooring regulates temperature. It has insulating qualities. Its lifespan can be extended with the right maintenance. But sometimes, the murram floor needs great care as compared to the mud floor.

Murram Flooring

2. Brick Flooring

Bricks are stacked in a herringbone pattern or flat. They can be fixed at an angle to the wall. It is highly durable and hard. Even brick flooring absorbs some moisture.

Brick Flooring

FAQ

Which countries are advised to construct mud floors?

Mud flooring is a common building material in tropical areas. Mud floors are inexpensive. It is reasonably waterproof. The floor’s construction is simple to install and maintain. Mud floors are warm in the winter and cold in the summer. So, they are ideal for locations with extreme seasonal temperatures.

Is Mud Flooring An Outdated Option? Or Not?

Maybe. In rural areas, people always prefer mud floors. But in the case of cities, it is an underrated option. Thus, that is not the issue. The argument is for the need for a fundamental understanding of mud floors.

Conclusion

In short, this article gives you well-explained information regarding mud flooring. Hoping you find your queries with the help of this article. If you have any inquiries then let us know in below comment section.

Also Read: 20 Sustainable Innovative Eco-Friendly Building Materials

Thank you for sharing insights on mud flooring. Its eco-friendly and cost-effective nature makes it an intriguing option for sustainable construction projects.