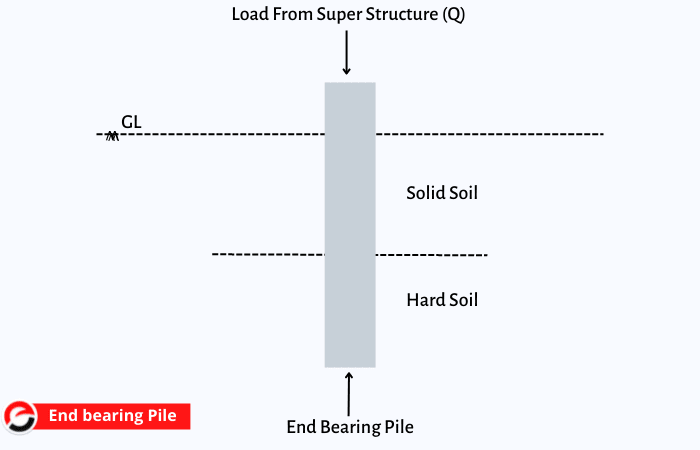

Definition: End bearing piles are a type of pile that works on the base of the mechanism of load transfer through the bottom tip of the pile itself. It means that it is used to transfer superstructure load through low-bearing capacity soil to the hard stratum like rock or any solid dense sand and gravel.

End bearing Pile

End bearing pile is also known as point bearing pile. This is used to transfer load through the bottom tip of the pile itself. End bearing piles are driven into the ground in such a way that the bottom end of the pile will be rest in between the weak soil layer and solid soil layer. So the end bearing pile act as a column that transfers superstructure load to the underlying soil.

We can determine the bearing capacity of the pile by multiplying the area of the bottom tip of the pile and bearing capacity at a confirmed depth of soil at which the pile rest.

End bearing capacity of pile calculation

end bearing capacity of pile calculated by two methods:

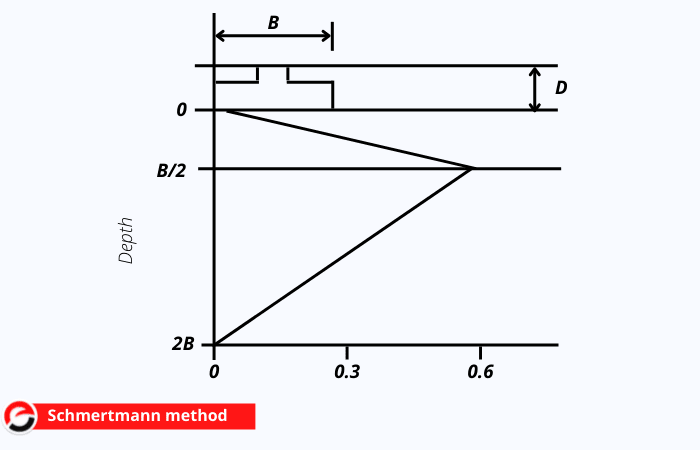

Schmertmann method

This method of end bearing capacity of pile determination was proposed by Schmertmann.

The following equation is used in this method for the unit end bearing capacity of the pile from the cone tip resistance:

qt = (qc1 + qc2 ) / 2

where, qc1 = the minimum average cone resistances of zone ranging from 0.7D to 4D below the tip of the pile.

qc2 = the average of minimum cone tip resistance over a distance of 8D above the tip of the pile.

D = depth of the end-bearing pile.

Tumay and Fakhroo

This method is used to calculate the ultimate bearing capacity of the end-bearing pile in clayey soil.

The Equation for determining used as follow:

qt = ( qc1 + qc2 ) /4 +( qa /2 )

where-, qc1 = average value of the qc values at 4D below the tip of the pile

qc2 = average of the qc minimum values at 4D below the tip of the pile.

qa = average of the qc minimum values at 8D above the tip of the pile

Effective length for end bearing pile

The effective length of the end bearing pile should not be more than 20 m and geo category 2. If pile length will be between 20- 30 meters then the bearing capacity should be reduced by 10 res. 25%.

End bearing pile settlement

end bearing pile will act greatly with the minimum settlement, so it will be a perfect choice for the building which settlement is critical when it is having a considerably heavy load. It will help to minimize large fluctuations in subsoil water levels.

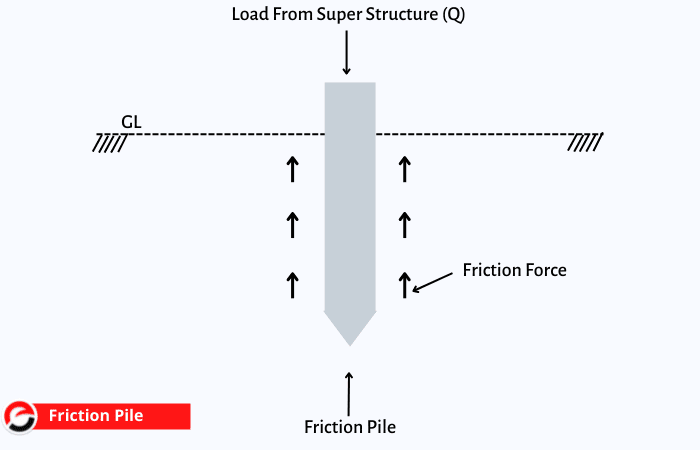

Friction pile

A friction pile is a kind of pile foundation. This kind of pile uses frictional force as a base between the pile base surface and adjacent soil surface to transfer the load of the superstructure. As per the soil strata condition, resistance force which is a frictional force here can develop a particular length of the full length. A friction pile is mostly used because for a stable foundation friction force is adequate.

End bearing pile diagram

Also read: Under Reamed Pile

End bearing piles advantages

Advantages of end bearing pile are:

- It has a low settlement on subsoil strata compared to any other type of pile like floating pile. So mostly multi-story buildings are constructed on this kind of pile.

- This is the most generous used pile on any construction site.

- Based on specification and need end bearing pile can be precast also.

- End bearing pile can be prefabricated in any kind of length, size, or shape as per the specification and used on-site so the time would be reduced for the completion.

- End bearing pile generally does not have any buckling failure in weak soil, except if it passes through water or air.

- Pile rest on the solid firm strata than the steel for carrying the maximum load that can be applied on it.

- Construction cost of the pile can be reduced as per the length as specified based on the depth of the firm soil base layer.

- The length of the pile which is gone used can be easily computed based on bedrock depth obtained from earlier borehole records of soil exploration.

End bearing piles disadvantages

disadvantages of end bearing the pile are:

- Big heavy machinery is needed for the construction of end-bearing the pile and causes more cost for construction.

- The surrounding soil of the pile may come to the surface of a pile and causes negative skin friction on the pile.

Difference between end bearing pile and friction pile

| End bearing pile | Friction pile |

| When a pile transfers a load of superstructure through weak soil strata to a suitable firm bearing strata at a greater depth then these piles are called an end-bearing pile. | When piles transfer the load only a mean by skin resistance without any firm end bearing then the piles are called friction piles. |

| a load of the superstructure is taken by the hard soil stratum. | Load is taken by the friction developed between the side of the pile and the surrounding soil or ground. |

| A Hard stratum is essential. | A Hard stratum is not essential. |

| It is used to transfer load from water or soft soil. | It is used to transfer load through a depth of friction occurring. |

Difference between skin pile foundation and end bearing foundation

| skin pile foundation | End bearing foundation |

| skin pile foundation is based on transferring the load through the skin friction between the side of the pile and surrounding soil or ground. | End bearing foundation is based on transferring the load on the hard stratum through soft soil. |

| Skin pile foundation takes the load on its skin surface throughout. | End bearing pile directly transfers the load at the bottom tip of a pile. |

Also Read: Equivalent & Effective Length of Column for Various End Conditions

FAQ

How short can an end-bearing pile be?

It depends on the depth of the hard soil stratum.

How to fix the length of end bearing pile in bridges?

The Length of the end bearing pile can be fixed based on load calculation and depth of hard soil strata.

Where to use the end bearing pile?

End bearing pile is most preferably used for high-rise buildings and towers, major water tanks and reservoirs, and bridges.

End bearing piles transfer structural loads to deeper, stronger soil or rock. Calculations involve determining load capacity and effective pile length. Advantages include high load capacity and reduced settlement, making them suitable for weak soils. Disadvantages include high installation costs and potential noise, making site conditions crucial for success.