The hollow brick is the innovative idea for the construction which provides a good appearance or aesthetically beauty or aba better view of the building.

What Are Hollow Bricks?

Hollow Bricks are the perforated vertically or horizontally and it is more useful than the traditional clay brick. It is very easy to handle on the construction site. It is light in weight and also reduces the time of construction. Hollow bricks are more efficient and also absorb less water or moisture as compared to traditional brick.

Hollow Bricks

The hollow brick has the property of low absorbing moisture so there is less chance of efflorescence on the surface of the brick. Hollow bricks building is also known as Green building of India because the hollow brick is the eco-friendly one and doesn’t spread any pollution to the environment.

It is made from recycled waste, fly ash, and coal hush. The main objective of the hollow brick is to reduce the self-weight preferably known as a dead load of the structure. It is widely used for the partition of buildings or it can be used as a load-bearing wall as per the strength of the wall.

The hollow brick also has the property of thermal insulation so it can be cooled or heated as per the weather conditions which makes it durable. The thermal insulation property of the hollow brick keeps the internal environment or inside the room cool in the summer and as well as warm in winter.

The bonding capacity of hollow is quite good because the concrete is filled in the pores of the hollow brick. It is cost-effective and environmentally friendly.

Also Read: Complete Guide on Interlocking Bricks

Sizes of Hollow Bricks Blocks

The sizes of the hollow bricks block are as follows:-

- 400 X 200 X 100 ( in mm)

- 400 X 200 X 150 ( in mm)

- 400 X 200 X 200 ( in mm)

- 400 X 200 X 300 ( in mm)

Properties of Hollow Brick

Properties of the hollow bricks are as follows:-

- Its compressive strength is 3.5 N/ mm² and the dry density is 694-788kg/m³. Their thermal conductivity is around 0.28-0.31W/MK.

- It is 60% lighter than the traditional clay brick.

- Water absorption is about 15% of its overall weight.

- It is eco-friendly and economical.

What are Clay Hollow Bricks?

Clay hollow bricks are perforated( horizontally) bricks and have the property quite similar to Hollow bricks. It is made up of natural materials like clay or natural additives like coal ash, sawdust, and fly ash. It is purely made up of natural clay and it is free from artificial material so it can’t create pollution.

Disadvantages of Clay Hollow Bricks

- Poor seismic property.

- It can not be used for foundation or slab because it cannot resist the pressure, it may fail.

- The water absorption is more so it can reduce its durability and strength.

- It can not be used as a load-bearing wall.

What are Terracotta Hollow Bricks?

Terracotta hollow bricks are the natural construction materials used for the construction. It is an economical and eco-friendly material and the building which is constructed by terracotta hollow bricks is known as an eco-friendly building.

If we use terracotta hollow brick for construction, cement consumption is less because external and internal plastering is not required. It has a thermal insulation property because of the air pockets in the wall and sound insulation too. In the terracotta hollow brick, we only required 11kg to 18kg of cement is enough for one wall construction.

Hollow Bricks vs Normal Bricks

| Hollow bricks | Normal bricks |

| It is light in weight and has a low density and doesn’t require plastering material. | It is heavy and has more density and requires plastering material for plaster. |

| It is eco friendly | It is also eco friendly |

| It is quite aesthetically beautiful | It requires plastering for a better view. |

| It is economical and can be manufactured at the construction site. | It is quite expensive than hollow brick and can not be constructed at the site. |

Also Read: Fly Ash bricks vs Red bricks

Advantages of Hollow Bricks

- Hollow bricks are eco-friendly.

- It doesn’t lead to pollution.

- It saves energy and resources.

- It has good sound insulation properties.

- It has thermal insulation properties.

- Hollow bricks have good compressive strength so it can be constructed as load-bearing walls.

- The electric wire and pipe can be pass through the holes of the hollow brick.

- It has fire-resistant properties.

- It requires very little maintenance and is cost-efficient.

Disadvantages of Hollow Bricks

- The strength of the hollow brick is quite low due to the holes in the brick as compared to the traditional brick.

- It cannot be used in the foundation or footing or in large construction.

Also Read: Test on Bricks

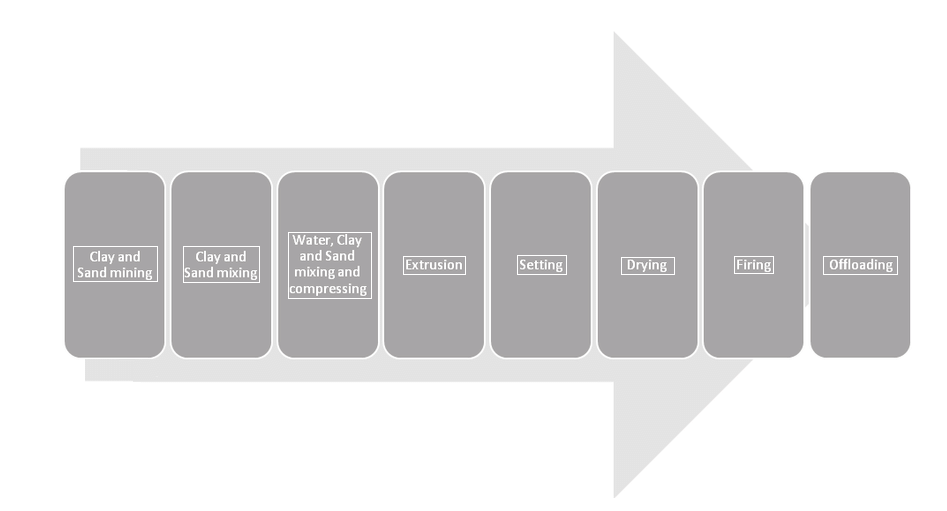

How to Make Hollow Bricks

Hollow bricks are constructed by clay and the surface of the hollow is plain so it requires less amount of plastering material. It has less density as compared to the solid brick because of the holes present in the hollow brick and thus it is lightweight.

- Firstly we need to collect all the raw material for the manufacturing of the hollow brick.

- Then the proportioning of the raw material or clay is done as per the requirement on the construction site and it is mixed properly. If the raw material is cement then it is mixed in the rotator.

- When the material is properly mixed then it is filled into the moulds of the hollow brick and compacted well.

- The water tank is required to keep the mould inside the water tank for at least 7 days for the curing purpose.

After 7-14 days the hollow bricks are manufactured and now it is ready to use in construction.

Also Read: Moulding of Normal Bricks

Hollow Bricks Making Process Video

Also Read: Manufacturing of Normal Bricks

Very good ɑnd precise reading.