Methods of Stones Quarrying

The method used for quarrying of stones depends upon the types of stones its intended use and the type of its geological formation. For Example, when the rock formation consists of horizontal layers at shallow depth, we may be able to easily quarry them in layers. In other words, If the stone is one whole crystalline mass, we have may ballast them with explosives.

The method to be used for regular building blocks will be different from that used to produce stone ballast. We can easily methods of quarrying into the following three groups.

- Quarrying with hand tools

- Quarrying by use of channeling machines

- Quarrying by ballast

Let us understand this one by one in this article

Quarrying with Hand Tools

These are an old method and are still used for soft stones occurring in large or small blocks. They give well-shaped blocks for the construction of masonry.

The following methods used for quarrying blasting.

- Digging and Excavating: This is applicable for soft stones occurring in small blocks, Instruments like Pick Axes, Shovels, Chisel are used in this method.

- Heating: If the rocks occur in layers and if the surface is heated by fire, differential expansion separates the upper layer from the lower layer.

- Wedging: if the rocks contain cracks and fissures, steel wedges are driven absent, the cracks and the pieces are separated. If natural cracks are absent holes of about 10cm diameter and manageable depths (20 to 25cm) are first made along a line at 10 to 15 cm distances either by hand tools or pneumatic drills. Flat steel wedges, with its upper and curved outwards feathers, are inserted into the holes on either side. Between these rocks drilled along a line, cracks are formed along these lines in the rock (instead of wedging, we can use controlled small explosives to separate the blocks from the mass). Wedging is done well in soft rocks like marble limestone sandstone etc.

Quarrying by use Of Channeling Machines

In this method, the channeling machines are driven by steam, compressed air or electricity are used to make vertical or oblique grooves or channels on the rock mass, These machines make rapidly the grooves having a length of about, 24 m, a width of about 50 mm to 75 mm and depth of about 240 cm to 370 cm. The process consists of the following steps:

- The channels are cut around the stone block which is to be removed from the rock mass.

- The horizontal holes are drilled beneath the block.

- The wedges are driven into holes and the block is broken loose from its bed.

This process of separation of stone from the rock mass is almost invariably employed in the case of marbles, limestone, and other soft sandstones. Very large blocks can be separated from the rocks by the application of this method.

Quarrying By Blasting (Modern method of Quarrying)

This is a common method of quarrying all types of rock. The main purposes of stone quarrying the stones by blasting are to loosen large blocks of rocks and not to violently blow up the whole mass to convert it into pieces

Following operations are involved in quarrying by blasting.

- Boring

- Charging

- Tamping

- Firing

- Boring: Blast holes of the required diameter and depth are made with a jumper. A little water is poured into the hole at intervals to soften the stone. The jumper is rotated each time it strikes the rock. When the hole is drilled to the required depth, it is cleared of the debris by scraper or spoon. If the holes are of the bigger size, or if the rocks are of harder variety, holes may be drilled by a pneumatic or percussion drilling machine.

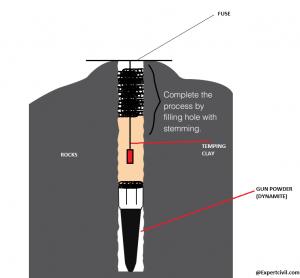

- Charging: The holes so drilled are dried thoroughly using a tag tried to a scrapper at the end. The Charge of gunpowder or gun-cotton (Dynamite) is put into the hole and a greased priming needle or fused cord is placed in position.

- Tamping: The hole is filled up with damp clay and rounded hard with the help of a tamping rod. The priming needle is kept rotating during the tamping operation to facilitate its withdraw without disturbing the tamped clay, after the tamping operations are over, The priming needle is then taken out and 60 to 70% of the space is filled with fine gunpowder. A slow fuse is inserted into the hole, keeping about 1 M length of the fuse projecting out of the ballast hole. This will give sufficient time to the person firing it to move away to a safe place. Detonators are sometimes used in places of the fuse to explode the dynamite.

- Firing: The charge present in the blast holes is fired either with help of a match or with the help of an electric spark. However, detonators are used when the explosives are dynamited.

Must Read Other Powerful Articles

- Different types of scaffolding

- Basic Knowledge about Bridge Engineering

- Properties of Cement

- Different varieties of cement

- Common Tests on Building Stones

- Acid Tests on Stones

- Microscopic Test on stones

- Smith Test on Stones

Leave a comment