Expansion Joints in Building

Expansion Joints are also known as Movement Joints. These joints are the gaps between the structure, simply the separation to let the structure expand or reduce stresses due to the change in temperature in its surrounding. These gaps are filled with an expansion joint system to make sure a complete building enclosure, workability, waterproofing, to absorb vibration, allow movements due to earthquake and ground settlement and hold the parts, etc. of the structure.

Expansion joint system stimulated to the seismic standards systems and supports. These systems of joints allow 25% of joint width for movement in the structure.

Not only thermal pressure, moisture and sway caused by wind, differential movements are also responsible for the expansion and contraction in the joints of the structure.

Also Read: How many types of cracks can occur in a building?

Requirements of Expansion Joints

These joints are very important in any construction whether it is residential or commercial.

- These joints are provided to prevent the failure of the expansion in the structure due to temperature change.

- These joints allow thermal expansion and contraction without any stress to the structure.

Characteristics of Expansion Joints

Characteristics of the expansion joints are as follows:

- An expansion joint is designed to absorb the expansion and contraction of the structure, absorb vibrations, and allow soil movements due to earthquakes or settlement.

- It is a disconnection between the portion of the same structure.

- In concrete block construction these joints are called as control joints.

- These joints are capable to handle the stresses without harming the structure

- These joints are generally located in between the parts of the structure.

Advantages of Expansion Joints

Some important advantages of Expansion Joints are as follows:

- These joints are very simple in design and also very simple functioning

- These joints reduce the space, weight, and cost of the structure

- These joints have better flexibility and durability

- These joints are reliable

- These joints reduce the complexity in the design of the structure

Expansion Joints according to IS 456 : 2000

- Expansion joints shall be provided so that the movement occurs in the structure with the minimum resistance at the joint.

- The structure adjacent to the joint should be preferably supported on separate columns and walls but not necessarily on separate footings/foundations.

- Reinforcement shall not extend across an expansion joint.

- Structures exceeding 45m in length are designed with expansion joints.

- The length of the structure where expansion joints have to be provided depends upon various considerations, such as weather exposure, temperature, season of laying, time of laying, quality and quantity of laying, etc.

Also check: IS Code For Concrete Structures [PDF Download]

Types of Expansion Joints

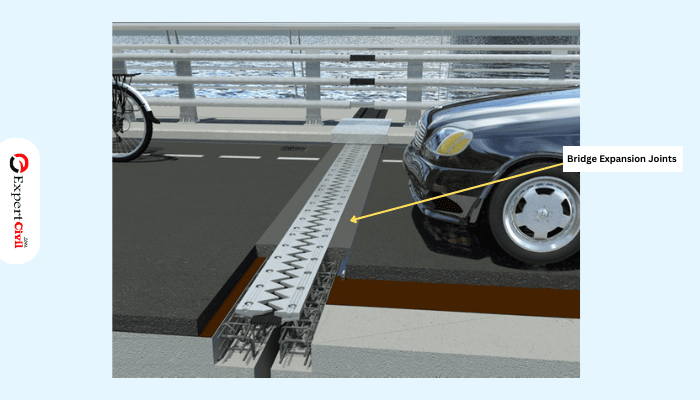

1. Bridge Expansion Joints

These are the joints provided in the bridges, roads or large slabs. These expansion joints are designed in such a way that heavy traffic can be allowed over them. These joints can carry continuous traffic over them during shrinkage, temperature change, vibrations on reinforced concrete, composite and steel structures, etc.

Bridge Expansion Joints

2. Masonry Expansion Joints

These are the joints given in masonry works. Clay bricks used in construction expand with heat and moisture. This causes compression stress on the bricks and mortar. This stress may cause failure. To overcome this failure, a joint can be replaced with an elastomeric sealant that will absorb the compression stress acting on the structure without damaging the structure.

Masonry Expansion Joints

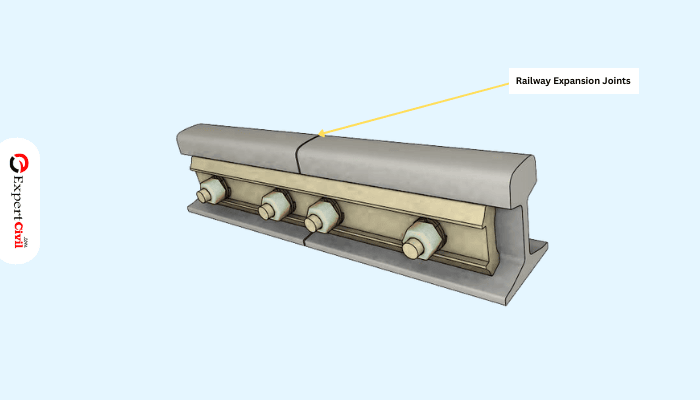

3. Railway Expansion Joints

Railway tracks may expand or contract due to temperature changes in the surroundings. But it is not necessary to provide expansion joints in railway tracks. It becomes necessary when the track is laid on the bridge or road having expansion joints. When the track base is a bridge or concrete road having expansion joints then it becomes mandatory to provide expansion joints in the tracks too.

Railway Expansion Joints

4. Pipe Expansion Joints

These expansion joints are provided in the machines of factories, industries, etc. These joints are necessary for the systems of pipe where high-temperature products such as steam, exhaust gases, and vibrations are conveyed.

Pipe Expansion Joints

Expansion Joints Based on Materials

On the bases of the material used, expansion joints are also classified into the following types

A. Rubber Expansion Joints

These expansion joints are very flexible in nature. These are made up of natural or synthetic elastomers and fabrics with metallic reinforcements. These provide stress relief in the piping systems from thermal changes. It is widely used in water supply and drainage systems. It is also used for the piping for recycled water, air conditioning, compressor, etc. Problems like vibrations, noise, shock, corrosion, abrasion, stresses, load stresses, equipment movement, etc. can be easily solved with these expansion joints.

B. Metallic Expansion Joints

These expansion joints are used in pipe work and duct systems to control the damage caused by vibrations, pressure, forces, temperature, etc. These joints are made up of stainless steel and high-grade nickel alloy steel. The main application of these joints is to make the best passage of heat and air into the pipe. These joints are applied with the compressors at the inlet and outlet of the pipe. These are also applied with the hot water and fire protection system.

C. Teflon Expansion Joints

These expansion joints are corrosion-proof and have good flex life. These joints are widely used in chemical processing industries. These are totally capable to carry acids and highly corrosive chemicals without damaging the pipe or other materials. These joints are non–ageing with extraordinary flex life. These have very unmatched reliability. These joints can compensate for angular deflections, vibrations, movement, misalignment, axial travel, etc.

D. Fiber Expansion Joints

These are expansion joints which are composed of fibers. These are made up of materials which are composed of fibers and uniformly saturated with asphalt to assure durability. These joints are also economical.

E. Toroidal Expansion Joints

These are joints in which the circular tube is fixed at the ends of the pipe to connect easily with another pipe. These joints allow axial strokes when there will be a temperature change, expansion and contraction of the pipe.

F. Gimbal Expansion Joints

These are the expansion joints in which angular rings or hinges are used in the joints and the rings are known as gimbal rings. These joints are designed to allow angular movement at the joint of the pipe and restrain the pressure from shear forces and internal forces inside the pipe. These rings are either circular or square. These joints can accept bending or angular movement at any plane.

G. Universal Expansion Joints

These are the expansion joints that allow the movement of the joint in three directions i.e. axial, lateral and angular cumulatively. These joints can be exposed for torsion deformation, bending, compressing, lateral, tension, etc. These can also accept thermal expansion for their length with very high temperatures.

H. In-line Expansion Joints

These are the expansion joints in which the ties are present to connect the other pipe and are used to compensate for the line pressure without damaging the pipe.

I. Refractory lined Expansion Joints

These are the expansion joints which allow the pipeline to expand or contract according to the climate condition from hot to cold without damaging the system function.

Also Read: Common Mistakes on Construction Sites

Installation of Expansion Joints

According to Indian Standards, the minimum depth of the expansion joint is taken as 1/4th of the slab thickness. The gap in the expansion joint depends upon the type of material used, size, dimensions and surface such as vehicle pavement, floating floor, bridge, sidewalk, etc. In concrete slabs, there is a chance of cracks in expansion joints if there is improper mixing of concrete or curing.

Expansion joints can be installed in two ways:

- Pre-Concrete Installation

- After Concrete Installation

Pre-Concrete Installation

As the name indicates, these joints are prepared before the pouring down of concrete. An individual expansion joint is created by applying a flexible material along the entire joint length.

After Concrete Installation

Here, joints are built up in the poured concrete by specific tools after the completion of the setting process of concrete.

Treatment of Expansion Joints in Building

Treatment of the expansion joints depends upon the conditions of the damage to the concrete. Generally, there are two ways of concrete treatment:

#1 Damaged Expansion Joints

If the expansion joint has cracks and marks, then the joint starts to decay. This kind of damage may be occurred due to continuous traffic, water, age, etc. The process to repair such damage have the following steps:

- First, clean the surface of the expansion joint. Its surface should be free from dust, debris, etc.

- After cleaning, fill the expansion joint with the crack repair kit up to the damage over the surface.

- Allow it to cure completely for about an hour after that recut the joint again.

- After that install the backer rod and completely fill the joint with filler over the backer rod.

#2 Normal Expansion Joints

If the expansion joint is all okay you are just checking it from time to time. The process for such repair has the following steps:

- First clean all surfaces of the expansion joint free from dust, debris, etc.

- Fill in most if needed, if the backer rod was installed, then just fill the joint with filler.

Also read: What is Concrete Crazing – Causes and Treatment

Leave a comment