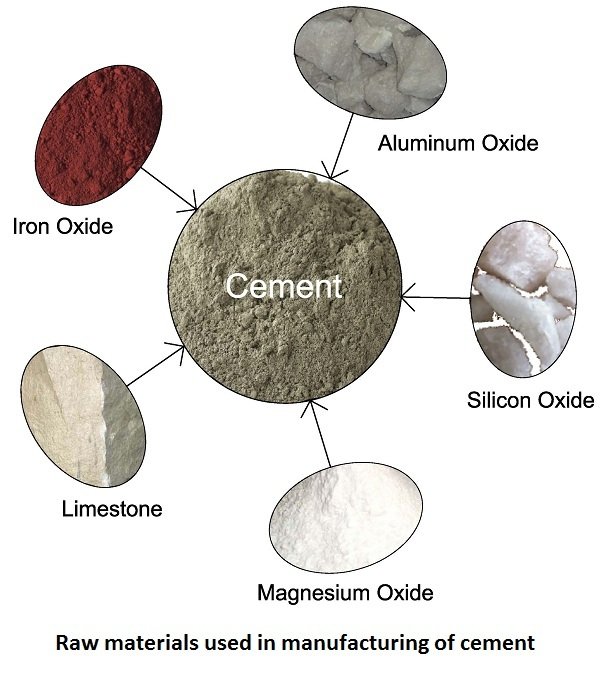

Raw Materials of cement

Do you know about Raw Materials of Cement, So let’s go and know about what are the raw materials used to make cement?

As we know that the main constituents of cements are Lime, Silica and Alumina.

The various ingredients of cement, their approximate percentage and range may be described as follows :-

Objective of Cement Ingredients

The ingredients of ordinary cement as mentioned above, perform the following functions:

Lime (CaO) : This is the important ingredients of cement and its proportion is to be carefully maintained. The lime in excess makes the cements unsound and causes the cements to expand and disintegrate.

On the other hand, if lime is in deficiency, the strength of cement is decreased and it causes the cement to set quickly.

Silica (SiO2): This is also an important ingredient of cement and it gives or imparts strength to the cement due to the formation of Di-calcium and Tri-calcium silicates. If silica is present in excess quantity, the strength of cement is increases but at the same time, its setting time is prolonged.

Alumina (Al2O3) : This ingredient imparts quick setting property to the cement. It acts as a flux and it lowers the clinkering temperature.

However the high temperature is essential for the formation of a suitable type of cement and hence the alumina should not the present in an excess amount as it Weakness the cements.

Iron Oxide (FeO3): This ingredient imparts color, hardness and strength to the cements.

Magnesia (MgO): The ingredient, if present in small amount, imparts hardness and colour to the cement. High content magnesia makes the cement unsound.

Calcium Sulphate( CaSO4): This ingredients is in the form og gypsum and its function is to increase the initial setting time of cement.

Sulphur (S): A very small amount of sulphur is useful in making the sound of cement. If it in excess, it causes the cement to become unsound.

Alkalies : The most of the alkalies present in raw materials are carried away by the flue gases during heating and the cement contains only a small amount of alkalies.

If they are in excess in cement, they cause a number of troubles such as alkali-aggregate reaction, efflorescence and staining when used in concrete, the brickwork of masonry mortar.

Some harmful constituents of cement:

The presences of the following two oxides adversely affect the quality of cement.

- Alkali oxides K2O and NaO2.

- Magnesium oxide MgO.

If the amount of alkali oxides exceeds 1 percent, it leads to the failure of concrete made from that cement. Similarly, if the content of magnesium oxide exceeds 5 percent, it causes cracks after mortar or concrete hardens.

It is due to the fact that magnesium oxide, burned at a temperature of about 1500 °C, Slakes very slowly, when mixed with water.

Must Read Other Powerful Articles

- Properties of Cement

- Types of Cement

- Composition of Cement Clinker

- Hydration of Cement

- Products of Hydration of Cement

- What is Cement?

- Various Tests on Cement

- Ordinary Portland Cement (OPC)

- Manufacturing of Cement By Dry and Wet Process

- Raw Materials of Cement

- History of Cement in Civil Engineering

- Composition of Cement Clinker

- Ordinary Portland Cement (OPC)

- What is Concrete with Definition & History

Leave a comment