What is concrete?

Concrete and cement are not the same things; cement is actually just a component of concrete. Concrete is made up of three basic components: like water, aggregate (rock, sand, or gravel) and Portland cement. Cement, usually in powder form, which is acts as a binding agent when mixed with water and aggregates.

This combination, or concrete mix, will be poured and harden into the durable material with which we are all familiar So lets read more about What is Concrete and Types of Concrete.

There are different types of binding material is used other than cement such as lime for lime concrete and bitumen for asphalt concrete which is used for road construction.

Various types of cement are used for concrete works which have different properties and also useful for applications.

Some of the types of cement are Following:

- Portland Pozzolana Cement (PPC)

- Rapid Hardening Cement

- Sulphate Resistant Cement

How to Make Concrete?

In Civil Engineering, there are two types of concrete mixes: nominal mix and design mix.

Nominal mix is used for normal construction works, such as small residential buildings, with the most popular ratio being 1:2:4 (cement, sand, and aggregate).

Design mix concrete is determined based on various lab tests, like cylinder or cube tests, to achieve the required compressive strength. This process is called mix design and ensures an economical use of ingredients.

Once suitable mix proportions are determined, the ingredients are mixed in the selected ratio.

Two main methods are used for mixing:

- Hand Mixing

- Machine Mixing

The choice between these methods depends on the quantity and quality required for the project.

After mixing, the concrete is transported to the casting location and poured into formworks. Different types of formworks are available and chosen based on their specific usage.

The poured concrete sets within the formworks for a specified time, depending on the type of structural member and the strength required.

Once the formwork is removed, curing is performed through various methods to replenish the moisture lost due to evaporation. Hydration reactions require moisture, which is crucial for setting and strength gain. Curing is typically continued for a minimum of 7 days after formwork removal.

Types of Concrete In Civil Engineering

Concrete may be the following types:

- Plain concrete construction (PCC)

- Reinforced concrete Construction (RCC)

Plain concrete construction (PCC)

In PCC, concrete is poured and cast without any reinforcement and is used when structural members are subjected only to compressive forces, without bending.

Reinforced concrete Construction (RCC)

In RCC, where structural members experience bending, reinforcements are added to withstand tension forces, as concrete is weak in tension compared to compression. Typically, concrete’s strength in tension is only 10% of its strength in compression.

It is used as a construction material for almost all types of structures such as residential concrete buildings, industrial structures, dams, roads, tunnels, multi-story buildings, skyscrapers, bridges, sidewalks, and superhighways etc.

Example of famous and large structures made with concrete are Hoover Dam, Panama Canal, and Roman Pantheon. It is the largest human-made building materials used for construction.

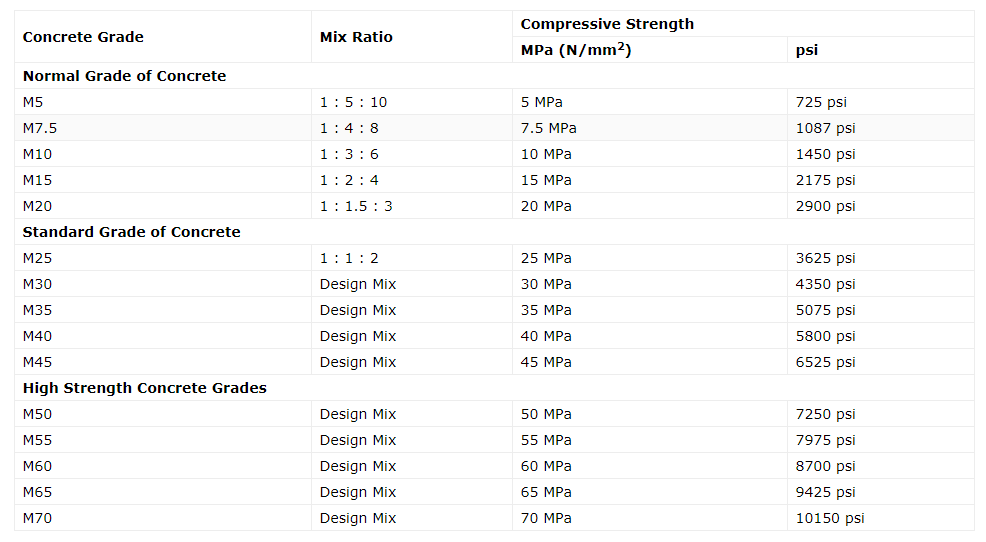

Grade of Concrete

Concrete is categorized into different grades based on its strength.

Steps For Concrete Construction

The steps for concrete construction include:

- Selecting the quantities of materials for the chosen mix proportion.

- Mixing the materials.

- Checking workability.

- Transporting the mixture.

- Pouring it into formwork for casting.

- Vibrating for proper compaction.

- Removing the formwork after a suitable time.

- Curing the member using suitable methods and for the required duration.

Frequently Asked Questions

What is the difference between cement and concrete?

Cement and concrete are often used interchangeably, but they are distinct materials. Cement is a fine powder used as a binding agent in concrete. Concrete, on the other hand, is a mixture of cement, water, and aggregates (such as sand, gravel, or crushed stone) that hardens into a solid material. In simple terms, cement is an ingredient in concrete.

What are the different types of concrete?

There are various types of concrete used in construction, including plain concrete (PCC), reinforced concrete (RCC), and specialty concrete mixes like high-strength concrete, lightweight concrete, and precast concrete. Each type has specific properties and applications depending on the project’s requirements.

How is concrete made?

Concrete is made by mixing cement, water, and aggregates in predetermined proportions. The process involves selecting the right mix design, combining the ingredients, and ensuring thorough mixing. Afterward, the concrete is transported to the construction site and placed in formwork, where it is left to cure and harden.

Why is curing important in concrete construction?

Curing is a critical step in concrete construction because it helps maintain the proper moisture levels required for the hydration of cement particles. Adequate curing ensures that the concrete gains its intended strength and durability. Without proper curing, concrete can become weak and prone to cracking, reducing its lifespan and performance.

Must Read Other Powerful Articles

- Different types of scaffolding

- Basic Knowledge about Bridge Engineering

- Important Things a Civil Engineer Must Know