What is Tie Beam?

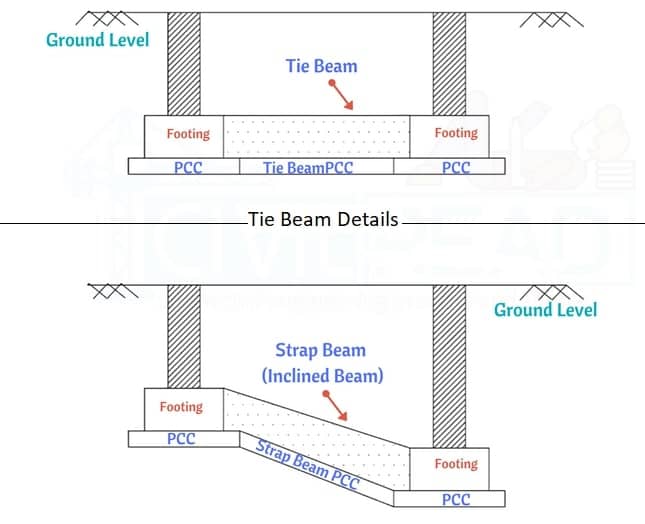

The beams which make the connection between two or more columns or rafters in a roof or truss or at any height above floor level to make the whole structure more firm and stable at the foundation level is known as tie beam.

Tie beams are generally provided at roof truss and floor level and a plinth. They are unable to carry any vertical load such as walls etc.

Tie beams sometimes act as a strap beam which bears all stresses due to the eccentricity of the vertical member (Columns) on the footing.

Tie beams works as fixing members to decrease the supported length of the column which is not supported.

Tie beams can also act as a support to walls or any other partition members among them. Tie beams can also work as a tieing element to protect the settlement between footings and the strata.

Also Read: A Complete Guide on Different Types of Beam and its Classification

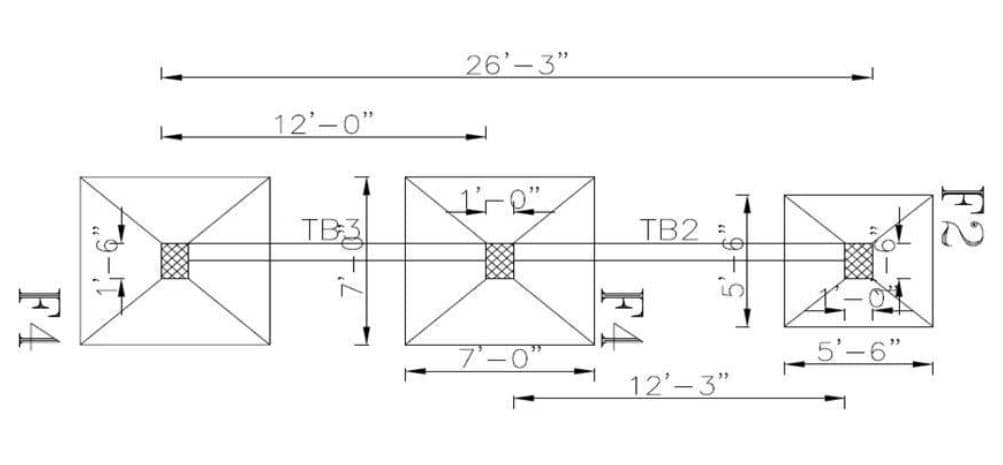

Tie Beam Details

When the roof or slab height is higher than the usual height of the structure, then these types of beams are provided in the building.

Tie beams act as a height breaker in the columns. Tie Beam connects two or more columns to reduce their effective length and decrease their slenderness ratio.

Advantages of Using Tie Beam

- Tie beams do not take any floor loads and act as a length-breaking member for columns where the floor is at a higher level than general height.

- Tie beams carry axial compression.

- Tie beams transfer the rafter’s load to the columns.

- Tie beams prevent outward buckling of highly stressed slender longitudinal columns.

- Tie beams connect column footings or pile clips.

- Tie beams hold longitudinal bars in their original position when concrete is being placed.

- Tie beams keep the spread footings in their respective positions during the seismic events.

- Tie beams serve as grade beams that redistribute vertical loads through moment and shear in the event of settlement.

- Tie beams serve as strip footings to support inner or outer walls.

- Tie beams serve as grade beams over a pile foundation to join the pile-caps and support the superstructures.

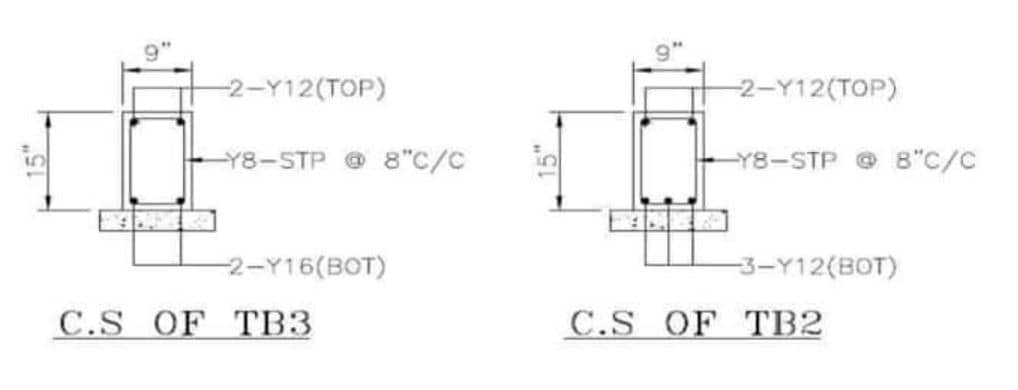

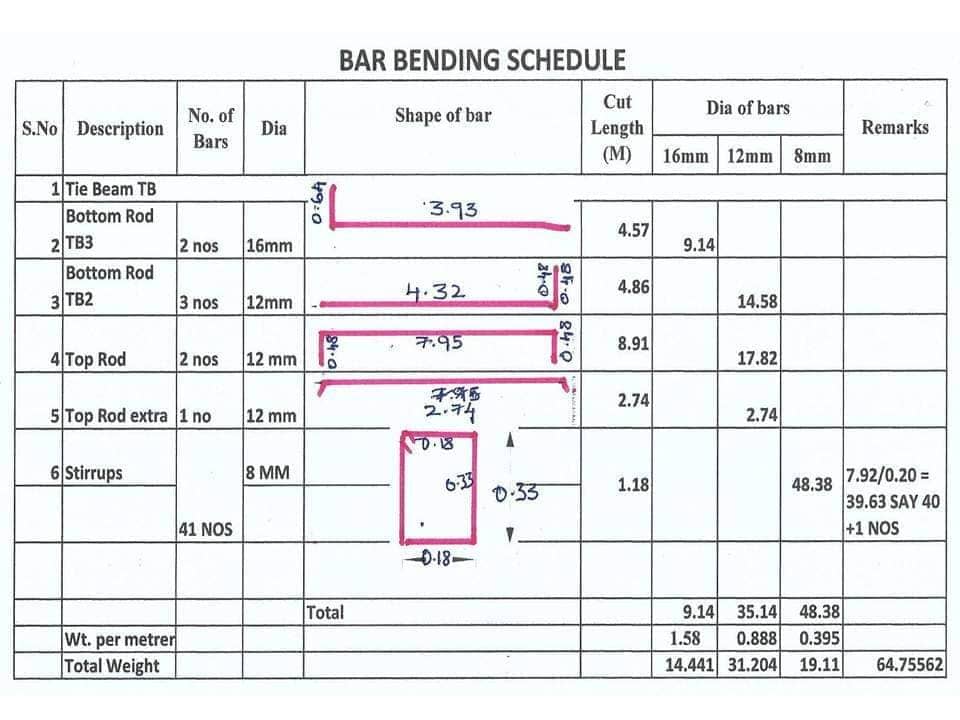

Bar Bending Schedule for Tie Beams

- The main purpose of the bar bending schedule is to find out the quantities of the reinforcement required for the building.

- Bar Bending Schedule for footings is essential for convection of knowledge on the tie beam/strap beam reinforcement for the substructure.

- Tie Beam can be termed as a beam that joints two footings in the substructure. If the two footings remain in a similar line, the tie beam should be set out.

- Strap Beam has the similarity to tie-beam, but strap beam joints two footings at a particular angle. Strap beam is used when two footings are at diverse levels.

- Tie beam/ Strap beam is particularly situated amid pile caps & shallow foundations. Their chief purpose is to force all shallow foundations or pile caps to obtain the same & minimum settlements.

- The horizontal reinforcement bars which connect one footing to another footing are of main bars and the vertical bars are termed as stirrups (rings).

- Stirrups help in holding the main bars in the exact position.

Tie Beam Reinforcement

The following points should be taken into consideration before the reinforcement of tie beams:-

- Main Bars (Top bar, Bottom bar and Sidebar) should be placed from the centre of one footing to the centre of another footing.

- Stirrups (rings) are provided from one side of the footing to another side of the footing.

- Proper Development length should be provided to main bars (top, bottom and sidebars)

- Stirrups should have a minimum spacing of 150 mm centre to centre.

- Stirrups should be made after deducting proper cover i.e. 25 mm.

- The length of hooks of the Stirrups should not be less than 10d (where d is the diameter of the bar).

- The hooks of the Stirrups should be bend at 135° for the prevention from earthquake pressures.

Ties in Column

Proper use of column ties for making a perfect structural design

- Firstly, straightening of the rods is necessary for making ties and maintaining the exact diameters. The minimum length of the rods used for making ties should not be less than 10mm.

- On the basis of measurements specified in the drawings, the rods should be cut and bend cautiously; otherwise, it gets waste.

- For maintaining the correct specification and spacing of the ties, we need to consult the design engineers and follow the codes provided by BNBC, ACI and ASTM.

To withstand an earthquake, the following detailing must be maintained for the ties:-

- The tie’s hook should be bent at an angle of 135°. The head part of the ties should be expanded up to 10d. For a 10 mm rod, it should be 100mm i.e 4 inches.

- Earthquake protection is also important for the ties located in the centre portion of the member.

- Before placing the ties in the bars of the columns, we need to clean the primary rods properly.

- After this, depending on the design and spacing of the ties, the required numbers of ties should be provided in the rods of the columns. At this time, the hooks of the ties should be bent and arranged properly.

- After placing the ties, fasten them tightly with the main rods of the columns with the binding wire (GI wire). We need to be careful that the ties should not be displaced from their position after fastened with wires.

- For earthquake protection, the ties should also be provided in the joints of beams and columns. Proper numbers of ties in the joints of beams and columns should be provided.

Tie Beam Design

- The term “Tie beam”, “grade beam”, “ground beam” and “plinth beam” do not have much difference, Tie beam is a beam which is used to join two columns to resist two movements vertically and horizontally.

- Tie beams can be provided at any level. If these are provided at plinth level, they are known as plinth beams, where it helps in soil retaining of inner area 9f the building and also provide support for the walls.

- The design of the tie beam depends upon the amount of settlement of the foundation selected for the work at hand.

Why Are Use Concrete Tie Beam?

- The steel braced framed columns are supported at a Spread Footing with tie beams between columns.

- To bear vertical and horizontal reactions from Frame by designing a tie beam we have to consider that has a general concrete beam with an axial load.

- This axial load works as compression or tension load so for axial compression-like axial column capacity. For required axial tension, Steel Area should also be checked properly.

- It is a tension member, not a compression member so, the only function of the concrete is to protect the steel and bear the compression.

- After checking the reinforcement, make sure you have provided the required lap at the required splices.

- Tie members do not need to be covered v with concrete, but they have to be protected.

- Reinforcement, always prefer to use couplers than using lapped bars.

Tie Beam Reinforcement Details

- Reinforced Cement Concrete (RCC) is mostly used for construction all over the world.

- The work of Columns is to transfer the loads from beams and slabs to the foundation.

- Columns can provide support to high compressive forces in large structures such as long-span structures and skyscraper buildings.

- Columns may suffer damage due to overloading and natural mishappenings such as earthquakes and fires because of the limited strength and ductility of cement concrete.

- If a failure occurs in one or more columns, it may result in a collapse of the building.

- Both longitudinal as well as lateral reinforcements are necessary for RCC columns.

- Even, either more spacing or less spacing between the ties can result in a shortage of confinement of concrete core.

- While the low volumetric ratio of ties reduces the strength of the concrete core, the high volumetric ratio of ties reduces concrete continuity. It makes a weak plane between the concrete core and the concrete cover.

Quantity of Reinforcement in Tie Beam (Calculation)

- Find out the total length of the tie beam.

- Find out the total dead load and live load according to the given drawing.

- Depending on load, calculate the maximum bending moment and shear force acting on the beam.

- Weight of 1 m of steel=d²/162 where d is the diameter of the bar) kg, From this Formula, how much weight of Reinforcement needed can be calculated.

Still, Do Have a Question? Ask a Question and Get an Instant Answer

A tie beam is a horizontal structural member used to connect and provide stability to two or more vertical members, such as columns or piers. It helps to prevent the horizontal movement or spreading apart of the columns, which can occur due to various loads and forces acting on the structure. Tie beams are commonly used in building construction, bridges, and other structures to enhance overall stability and prevent structural failure.

Tie Beam Details:

– Tie beams are typically made of reinforced concrete, as it provides the required strength to withstand the forces and loads acting on the structure.

– They are generally placed at or near the top of the columns and extend between the columns to form a horizontal connection.

– Tie beams may have different shapes and sizes depending on the structural requirements and architectural design of the building.

Tie Beam Reinforcement:

– The reinforcement in a tie beam is provided to enhance its tensile strength and prevent cracking or failure under loads.

– Steel bars, also known as rebar, are placed within the concrete to carry tensile forces. The rebar is embedded within the concrete in a specific pattern and configuration to provide the necessary reinforcement.

Advantages of Tie Beams:

1. Enhanced Structural Stability: Tie beams improve the stability of the structure by connecting columns and preventing horizontal movement, especially in regions prone to seismic activity or high winds.

2. Increased Load Carrying Capacity: Tie beams help distribute the loads more uniformly among the columns, increasing the overall load carrying capacity of the structure.

3. Prevents Column Sway: Tie beams resist lateral forces, reducing the potential for column sway and maintaining the structural integrity of the building.

4. Prevents Differential Settlement: In situations where the soil has different bearing capacities beneath various columns, tie beams can help distribute the loads and prevent differential settlement, which can cause structural issues.

Why Concrete is Used in Tie Beams:

Concrete is the most commonly used material in tie beams for several reasons:

– Strength: Concrete provides high compressive strength, making it capable of withstanding the heavy loads and forces exerted on the tie beam.

– Durability: Concrete is a durable material that can withstand environmental conditions, including exposure to moisture and weathering.

– Versatility: Concrete can be molded into various shapes and sizes, allowing for flexibility in tie beam design to suit specific project requirements.

– Adherence to Reinforcement: Concrete provides good adherence to steel reinforcement, ensuring the tie beam functions as a composite material to carry tensile forces.

Overall, tie beams play a vital role in ensuring the stability and structural integrity of buildings and other structures. They are essential components in reinforced concrete construction, providing strength and support to resist horizontal forces and prevent potential failure modes.