Definition

Pointing in simple terms is a mechanism to dig the damaged mortar from the joints in stone or brick masonry and replace them with freshly prepared mortar followed by a proper surface finish to the joints. the joints are either built of cement mortar or lime mortar. Damaged mortar is removed either by hand or by using a special pointing device.

Purpose of Pointing

- Repairs the damaged mortar joints of walls and other masonry structures thus preventing them from failure.

- Improves the aesthetics of the masonry building by enhancing the mortar joints with different shapes.

- Pointing also offers a smooth finish to the surface of the joint and makes it well-proof against the environmental exposure of water, air, dust, etc.

Method of Pointing

As per IS 2212:1991 Cl (6.5.3), In the process of pointing, first, the mortar in the joints that is destroyed or failed must be removed all around the square of that joint to a maximum depth of 15mm.

It is specified in the code that the mortar that is to be dug from the joint must be soft (it must be still green in color). Digging is achieved either by manually using hand chisels or mash hammers. Although this method of raking (digging) is time-consuming and tedious but it proved to be the most effective and is less prone to any damage to the masonry building elements during the process of digging the mortar.

To minimize time consumption and labor force many contractors prefer digging mortar using power-driven tools such as electric saws or grinding tools. But this method of digging is quite risk-taking especially when the laborers do not have skill in using power-driven tools as their lack of skill and knowledge in using such tools may damage the masonry elements of the building while carrying out the digging operation using power-driven tools.

Also Read: Advantages and Disadvantages of Construction Equipment

Once the digging is done, the joint surface that is being dug is cleaned to remove the excess mortar particles and dust by flushing water using a pipe. The joint region must be moist without any trace of running water before refilling the fresh mortar. The freshly prepared mortar for pointing is now poured on the moist surface of the joints and finally the joint is given a smooth finish and sealed from environmental exposure.

Mortar used for Pointing

Mortar is a mix obtained from the combination of fine aggregate, water, and binding material. Usually, sand is used as the fine aggregate and the binding material may be cement or lime for brickwork and stone masonry.

Lime mortar preparation

The lime used for the preparation of lime mortar is fat lime and hydraulic lime. If fat lime is used then the lime mortar prepared is in the ratio 1:2 or 1:3 where the volume of sand is twice or thrice the volume of lime. If hydraulic lime is used then the mortar is prepared in the ratio of 1:2. The lime mortar is prepared either by pounding or grinding operation. If the production of lime mortar required is low then pounding is used while for the huge production of lime mortar grinding operation is used.

Cement mortar preparation

Usually for pointing work cement mortar is more preferred as compared to lime mortar.

Cement mortar is usually prepared manually (by hand) when the production is less. First, the dry cement and sand are mixed together then to this dry mix the required amount of water is added in gradual amounts and the mortar is prepared using hand shovels.

For huge production of cement mortar, mechanical vibrators are used. The cement mortar is prepared in the ratio of 1:2 to 1:3 for pointing work in masonry.

Also Read: Technical Terms used in Brick masonry

Different Types of Pointing

There are 8 different types of Pointing such as:

- Flush Pointing

- Keyed Pointing

- V-Pointing

- Beaded Pointing

- Weathered Pointing

- Struck Pointing

- Recessed Pointing

- Tuck Pointing

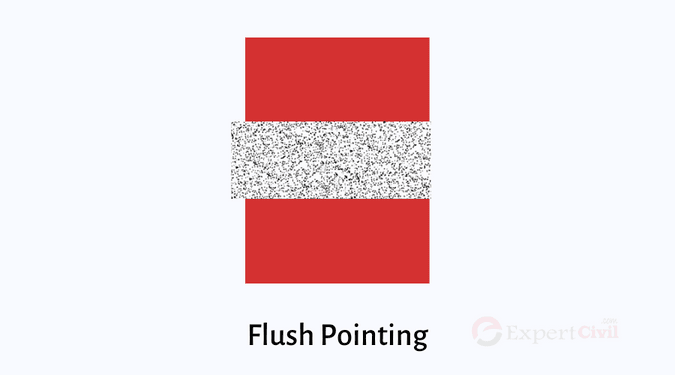

Flush Pointing

In this method of pointing the damaged mortar is dug along with the squares of the brick masonry joint. The surface is cleaned and made moist as explained above in the method of pointing.

The freshly prepared pointing mortar is now poured on the moist surface up to the level of the edges of the bricks. The surface of the joints is given a smooth finish in line with the edges of the bricks connected with the joint using a trowel and the excess mortar is removed using the trimmer.

Keyed Pointing

In this method, the fresh mortar is refilled and provided a smooth finish to the level of the edges of the brick as done in flush pointing. Now when the mortar is still soft, a 6mm diameter steel rod is inserted along the length of the joint and then removed from an arc-shaped groove in the mortar joints.

This type of pointing is done for both horizontal and vertical joints but is widely adopted for vertical joints of the walls. They improve the aesthetics of the masonry walls.

V-Pointing (V-Grooved)

This method of pointing is carried out in the same manner as in keyed pointing. The only difference here is, that a V-shaped tool is inserted into the mortar joint instead of the steel rod as used in keyed pointing. This V-shaped tool is then removed to form a V-shaped groove in the joint.

Beaded Pointing

In this method of pointing, a steel rod with a concave shape is inserted in the refilled mortar joint all along the joint in order to form concave grooves. Such a type of pointing work gives enhanced look to the masonry joints but is easily subjected to damage.

Weathered Pointing

In this method, the pointing of the joint is carried out in the same manner as in flush pointing. The only thing that differs here is that after the mortar is refilled in the joint and is still soft, the laborer pushes the horizontal edge of the brick connecting the joint backward to a depth of around 3 to 6 mm using the pointing device, due to which the pointing mortar starts sloping from the top to bottom of the joint depicting the weathering action.

Hence this method of pointing is named weathered pointing. This type of pointing is done in horizontal joints (joints connecting the horizontal edges of the adjoining bricks).

Struck Pointing

In this method of pointing the joint is refilled with the mortar in level with the edges of the bricks. Now the top edge of the joint is pushed inside to a depth of 10mm as compared to its bottom edge which eventually creates a slope in the mortar of the joints.

This sloped mortar joint will offer good drainage to the rainwater and prevents any damage in the joints due to the absorption of moisture due to rainwater.

Recessed Pointing

In this method of pointing the fresh mortar is refilled in the joint where pointing is done and then the mortar is pushed back from the edges of the joint by a distance of 5mm or greater than 5mm. The edges that are pushed must be facing vertically.

This type of pointing although gives a good appearance to the masonry structure does not offer resistance to environmental agencies such as water, moisture, frost, snow, etc.

Tuck Pointing

In this method of pointing the same procedure is carried out as in flush pointing. When the filled mortar in the joint is still soft grooves that are 5mm wide and 3mm deep are made in the mortar joint. Now, these grooves are filled with cement putty.

In some cases, these grooves make a projection of around 3mm thus exceeding the face of the pointing joint. Such pointing is called Bastard Pointing or Half Tuck pointing.

Advantages of Pointing

- Repairs the damaged joints of historical masonry structures and retains their strength and durability.

- Provides shield to the mortar joints against the environmental exposure of rain, frost, snow, air, moisture, etc.

- Pointing reduces the maintenance cost of masonry structures.

- Enhances the appearance of the masonry walls and other masonry structures by providing an attractive aesthetic look.

Also Read: Different Types of Brick Bonding used in Brick masonry

Question And Answer

Which mortar should I use for pointing?

Usually, cement mortar in the ratio of 1:2 to 1:3 is used for pointing work.

Leave a comment