What is Isolated footing?

Individual columns are supported by the isolated footing. They might be steeped or have projections in the concrete foundation. Steel reinforcement is given in both directions in a concrete bed for heavily loaded columns.

- On all sides of the concrete bed, a 15 cm offset is usually supplied. In the case of brick masonry columns, a 5 cm offset is likewise provided in regular layers on all four sides. When it comes to concrete column footings, they might be slabbed, stepped, or sloped.

Isolated footings come in a variety of shapes and sizes, including spread, stepped, and sloped footings. The most common shapes are square, rectangular, and round. The soil condition and the pattern of exerted loads determine which type of footing is used. When columns are placed at relatively long distances, isolated footings are one of the most cost-effective types of footings.

Isolated footing

Isolated or single footings are structural elements that are used to transmit and distribute loads from single columns to the earth without exceeding the soil’s bearing capacity, as well as to prevent excessive settlement and provide enough protection against sliding and overturning. They are also employed when there are light column loads, when columns are not tightly spaced, and when the soil is uniform.

Types of Isolated Footings

Isolated footings are generally three types:

- Flat, Pad, Plain, or Reinforced Isolated Footing

- Stepped isolated Footing

- Sloped Isolated Footing

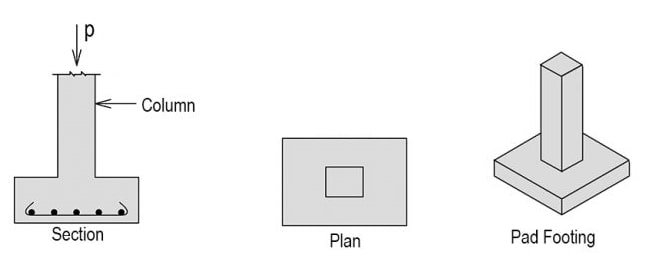

Flat, Pad, Plain, or Reinforced Isolated Footing

It is commonly square, rectangular, or circular in shape and is built separately under each column. Flat isolated footing has a consistent thickness. It’s included to help lessen bending moments and shear forces at important points. To boost the final weight carrying capability, it can be made of plain concrete or reinforced concrete.

Pad isolated footing

A pad foundation is built to sustain concentrated loads from a single point load, such as a structural column. Another name for this is a simple spread footing.

Stepped Isolated Footing

Construction of this form of isolated footing was once common, but its use has waned in recent years. It is primarily used in the construction of residential buildings.

Stepped isolated footing

The stepped footings are stacked on top of each other. To make steps, three concrete cross-sections are typically piled on top of each other.

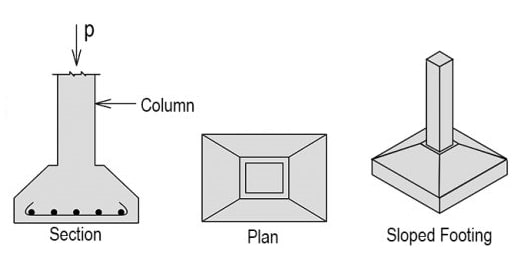

Sloped Isolated Footing

Sloped or trapezoidal footings are meticulously designed and built to maintain a 45-degree top slope on all sides. In the construction of a sloped footing,

Sloped isolated footing

less reinforcing and concrete is utilized than in the construction of a plain isolated footing. As a result, there is less need for concrete and reinforcement.

Also Read: Strap Footing – Its Types, Advantages & Disadvantages

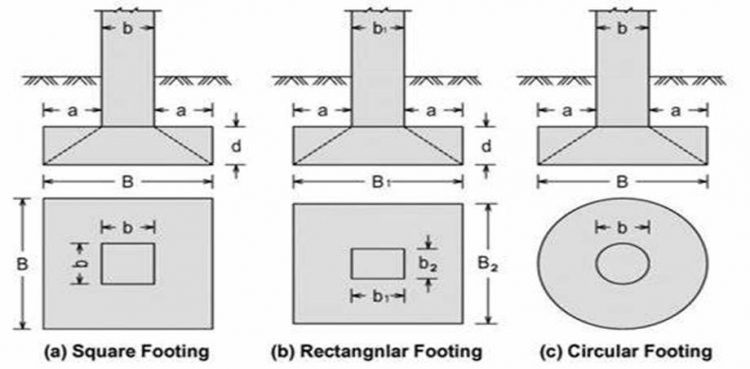

Different Shapes of Isolated Footings

- Square

- Rectangular

- Circular

Different Shapes of Isolated footings

Advantages of Isolated Footing

- Isolate footings are cost-effective.

- The independent footings are simple to build.

- Even unskilled workers can construct it.

- It necessitates minimal excavation of the earth.

Disadvantages of Isolated Footing

- The earth must be stable all the way around the structure’s base.

- It may be very huge in size to cope with the heavy load.

- Because of the separate foundations, this design is vulnerable to differential settlement that could harm the structure.

Isolated Footing Design

The purpose of isolated footings design is to determine:

- Location of the footing

- The thickness of the footing is measured in millimeters.

- Reinforcement Details of the footing, considering the gratifying moment and shear force.

- Check for shearing stresses and development length.

- All of this is done while considering the loads on the footings, the soil’s safe bearing capacity (SBC), the concrete grade, and the steel. On the surface of the contact with the earth’s face, the minimum cover to major reinforcement must be 50mm. The main reinforcement must have a diameter of at least 10mm.

Isolated footing

Design steps to be followed for isolated footing:

- Calculate the area of footings using factored loads.

- Assume a suitable footing thickness.

- Determine the flexure and shear critical sections.

- Calculate the bending moment and shear forces in the critical section.

- Examine the thickness of the expected layer.

- Look into the details of the reinforcement and make sure there are no bearing tensions.

- Check the length of the development process.

Also Read: Preparation of Bar Bending Schedule

Details of Isolated Footing Reinforcement

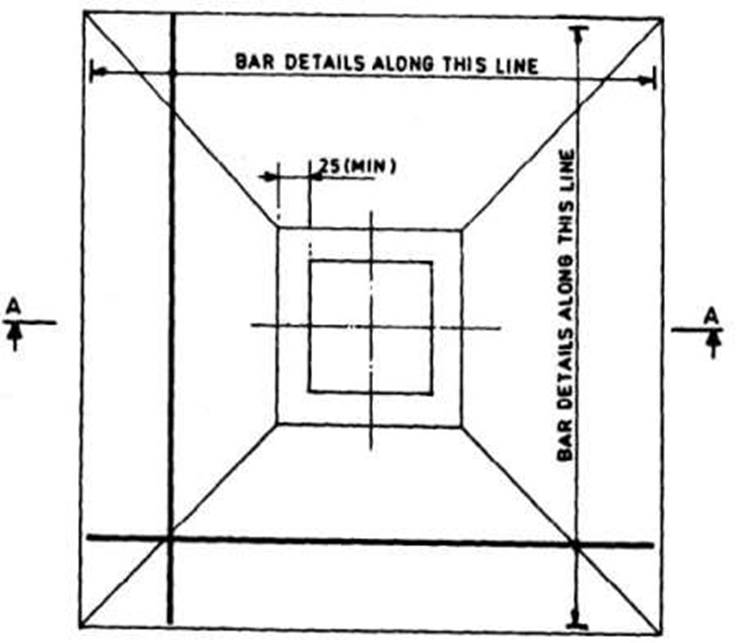

Footing reinforcement details are just as critical as site analysis for footing structural design. The footing’s design need for structural stability is reflected in the detailing. Cover-to-reinforcement based on environmental concerns for longevity, minimum reinforcement and bar diameters, and suitable footing dimensioning are all examples of good reinforcement details. In designs, a good foundation should be described in both plan and elevation. As a result, the following sections cover various aspects of isolated footing reinforcement detailing.

The following are isolated footing reinforcement details:

- Reinforcement concrete cover

- Bar diameter and minimum reinforcing

- Distribution of reinforcement in isolated footing

- Reinforcement with dowels

- Splice in the lap

According to IS 456-200, the minimum thickness of main reinforcement in a footing should be 50mm if the footing is directly in contact with the earth’s surface, and 40mm for externally exposed surfaces such as surface levelling PCC. If surface levelling is not used, a 75mm cover must be selected to cover the excavation’s uneven surface.

Minimum Reinforcement and Bar Diameter

The minimum reinforcement must account for 0.12% of the overall cross-sectional area. The main reinforcement should have a minimum diameter of 10 mm.

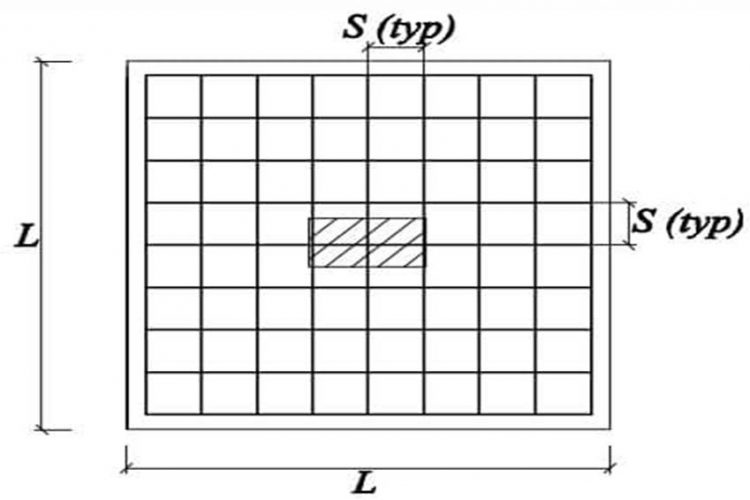

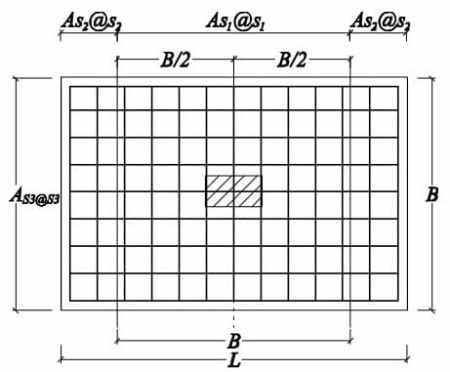

Footing Reinforcement Distribution

The reinforcement in a one-way RCC footing is evenly distributed throughout the whole width of the footing. The reinforcement extending in both directions is distributed consistently throughout the complete width of the footing in two-way square footings. In the case of two-way rectangular footings, reinforcement is spread in a long manner throughout the entire width of the footing.

The reinforcement is dispersed in the middle band for a short direction, as calculated below. In the short direction, the rest reinforcement is distributed evenly on both sides of the central band.

\[\frac{{{\text{Reinforcement in central band}}}}{{{\text{Total reinforcement in short direction}}}}{\rm{ = }}\frac{2}{{\left( {\frac{y}{x}} \right) + 1}}\]

Where y is the long side and x is the short side of the footing.

Reinforcement distribution in square isolated footing

Reinforcement distribution is rectangular isolated footing

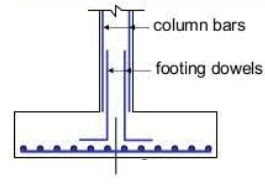

Dowel Reinforcement

To connect the isolated footing to the top column, dowel reinforcement is employed. The development length of dowel bars into the column and the isolated footing must be specified and clearly depicted in the design drawings when it comes to dowel reinforcement development.

Dowel bars Reinforcement details

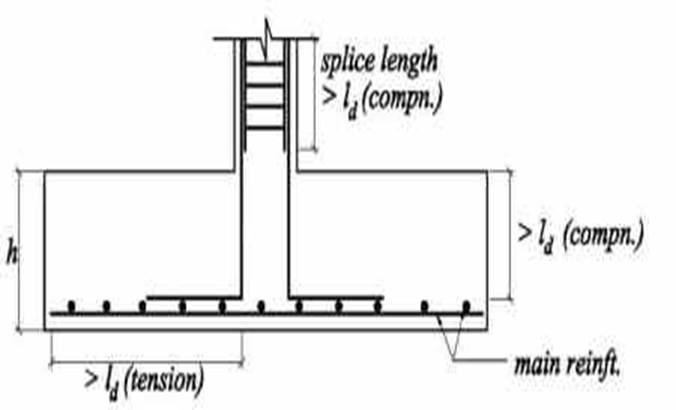

Lap Splice

The dowel and column reinforcement splice lengths must be readily visible. To prevent bond failure of the dowels in the footing and failure of the lap splices between the dowels and the column bars, the anchorage of both flexural and dowel reinforcement lengths must be monitored.

Anchorage reinforcement

Section view of reinforcement details of isolated footing

Plan view of reinforcement details of isolated footing (Typical Reinforcement details)

Also Read: Planning and Site Preparation for Concrete

Frequently Asked Questions

What is meant by isolated footing?

Isolated footings are frequently used for shallow foundations to carry and distribute concentrated loads, such as those induced by columns or pillars. Reinforced or non-reinforced material can be used in isolated footings. The height of the non-reinforced footing, on the other hand, must be greater to provide the appropriate load spreading.

Where is isolated footing used?

• When the columns are not closely spaced, this sort of footing is employed.

• There are fewer loads on the footings.

• The soil’s safe bearing capability is normally high.

How to calculate isolated footing volume?

Volume will be calculated based on its cross-section shape and thickness.

Isolated footing is a single-column foundation transferring loads to soil. Types include pad and stepped. Shapes vary. Advantages are economy; disadvantages include limited load capacity and performance on weak soils.