Moulding of Bricks

Moulding: The clay which is prepared as above is then sent for the text operation of moulding.

Following are two types of moulding:

- Hand Moulding

- Machine Moulding

Hand moulding: In hand moulding, the bricks are moulded by hand i.e.; manually. It is adopted where manpower is cheap and is readily available for the manufacturing process of bricks one small scale.

The moulds are rectangular boxes which are open at top and bottom. They may be of wood or steel. It should be prepared from well-seasoned wood. The longer sides are kept slightly projecting to serve as handles.

The strips of brass or steel are sometimes fixed on the edges of wooden moulds to make them more durable. It is prepared from the combination of steel plate and channel.

It may even be prepared from steel angles and plates. The thickness of steel mould is 6mm. They are used for manufacturing bricks on a large scale. The steel moulds are more durable than wooden one and turn out bricks of uniform size. The bricks shrink during drying and burning . The moulds are therefore made larger than burnt bricks (8-12%).

The bricks prepared by hand moulding are of two types:

- Ground moulded

- Table moulded

Ground moulded bricks: The ground is first made level and fine sand is sprinkled over it. The mould is dipped in water and placed over the ground. The lump of tempered clay is taken and is dashed is the mould.

The clay is pressed in the mould in such a way that it fills all the corners of the mould. The surplus clay is removed by wooden strike or framed with wire. A strike is a piece of wood or metal with a sharp edge. It is to be dipped in water every time.

The mould is then lifted up and raw brick is left on the ground. The mould is dipped in water and it is placed just near the previous brick to prepare another brick. The process is repeated until the ground is covered with raw bricks. The lower faces of ground moulded bricks are rough and it is not possible to place frog on such bricks. A frog is the mark of depth about 10mm to 20mm which is placed on raw brick during moulding.

It serves three purposes.

- It indicates the trade name of the manufacturer

- In brickwork, the bricks are laid with frog uppermost.

- It thus affords a key for mortar when the next brick is placed over it.

The ground moulded bricks of better quality and with frogs on their surface are made by using a pair of pallet boards and a wooden block. A pallet is a piece of thin wood.

The block is bigger than the mould and it has a projection of about 6mm height on its surface. The dimensions of projection correspond to internal dimensions of the mould.

The design of impression or frog is made on this block. The wooden block is also known as the moulding block or stock board.

The mould is placed to fit in the projection of wooden block and clay is then dashed inside the mould. A pallet is placed on the top and the whole thing is then turn upside down.

The mould is taken out and placed over the raw brick and it is conveyed to the drying sheds. The bricks are placed to stand on their long sides in drying sheds and pallet boards are brought back for using them again. As the bricks are laid on edge, they occupy less space and they dry quicker and better.

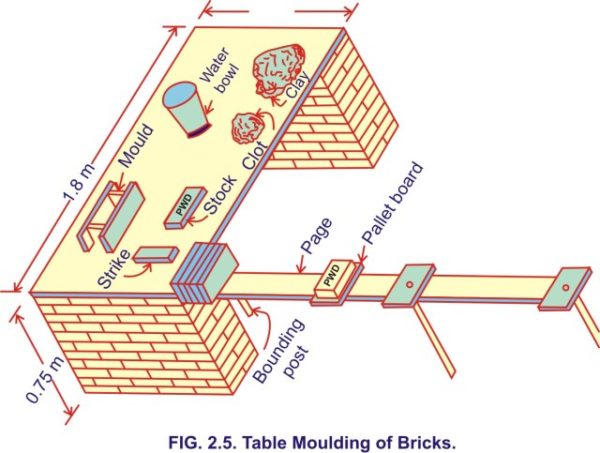

Table Moulded Bricks:

- The process of moulding of bricks is just similar as above. But in this case, the mould stands near a table size 2m x 1m. The bricks are moulded on the table and send for further process of drying.

- However, the efficiency of the moulder gradually decreases because of standing at some place for a longer duration. The cost of a brick is also increased when table moulding is adopted.

Machine Moulding

This type of moulding is carried out by two processes:

- Plastic clay machine

- Dry clay machine

Plastic Clay Moulding

- Such machine consists of a rectangular opening having length and width is equal to an ordinary bricks. The pugged clay is placed in the machine and it comes out through the rectangular opening.

- These are cut into strips by the wire fixed at the frame. The arrangement is made in such a way that the strips thickness is equal to that of the bricks are obtained. So it is also called as ‘WIRE CUT BRICKS’.

Dry Clay Machine moulding:

In these machines, the strong clay is finally converted into a powdered form. A small quantity of water is then added to form a stiff plastic paste.

- Such paste is placed in mould and pressed by the machine to form dry and well-shaped bricks. They do not require the process of drying.

- Calculation of Bricks Excel Sheet Download

- Manufacturing of Bricks

- Types of Cement

- Composition of Cement Clinker

- Hydration of Cement

- Products of Hydration of Cement

- What is Cement?

- Ordinary Portland Cement (OPC)

- Manufacturing of Cement By Dry and Wet Process

- Raw Materials of Cement

- History of Cement in Civil Engineering

- Composition of Cement Clinker

- Ordinary Portland Cement (OPC)

- What is Concrete with Definition & History

- Classification of Bricks

- Properties of Bricks

- Test on Bricks

Leave a comment