Quality Control and Monitoring Project Report

So finally today I’m going to be sharing PDF files on “Quality Control and Monitoring Project Report” I hope this is very powerful documents for all civil engineering students as well as employees who are working on site as a quality, site or structural engineers.

What is Quality Control in Civil Engineering?

In Construction industries Quality is the performance of the tasks which ensure that construction is performed according to plans and specifications, on time, within a defined budget, and a safe work environment.

It should be about proper planning, budgeting, risk analysis and building excellent relationships with the Client’s representatives on a daily basis.

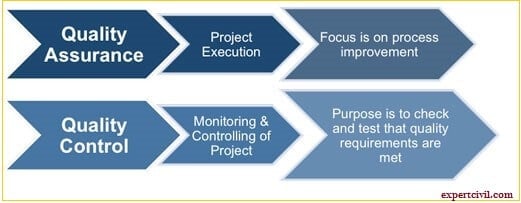

Difference Between Quality Assurance and Quality Control

There is a big difference between Quality Assurance and Quality Control Lets discuss some points on it

About Quality Assurance

- QA makes sure that we are doing the “Right Things the Right Way”.

- QA focuses on building in quality and hence “Preventing Defects “.

- QA deals with PROCESS.

- QA is for the entire Life Cycle.

- QA is a Preventive Process.

- QA is a Staff Function.

About Quality Control

- QC makes sure the results of “What we’ve done are What We Expected “.

- QC focuses on testing for quality and hence “Detecting Defects”.

- QC deals with PRODUCT.

- QC is for Testing Part.

- QC is Corrective Process.

- QC is a Line Function.

Contents of Quality Control and Monitoring Project Report

These following contents are mentioned in attached pdf files please download the file (Quality Control and Monitoring Project Report) and enjoy.

- Effect of poor technique on quality of construction

- TypeTypes of Cement and Testing of Cement

- Aggregates and Testing of Aggregates

- Displacement Method

- Calcium Carbide Method

- Electrical Meter Method

- Automatic Measurement

- Soundness of Aggregate

- Alkali-Aggregate Reaction

- Factors Promoting the Alkali-Aggregate Reaction

- High Alkali Content in Cement

- Availability of Moisture

- Temperature Condition

- Control of Alkali-Aggregate Reaction

- Grading of Aggregates

- Sieve Analysis

- Combining Aggregates to Obtain Specified Gradings

- Specific Surface and Surface Index

- Standard Grading Curve

- Crushed Sand

- Gap grading

- TESTING OF AGGREGATES

- Test for Determination of Elongation Index

- Test for Determination of clay, fine silt and fine dust

- Test for Determination of Organic Impurities

- Test for Determination of Specific Gravity

- Test for Determination of Bulk Density and Voids

- Mechanical Properties of Aggregates

Test for determination of ‘ten per cent fines value’ - Test for determination of aggregate impact

- Qualities of Water

- Use of Sea Water for Mixing Concrete

- Admixtures and Construction

- Chemicals

- Admixtures

- Plasticizers

- Superplasticizers

- Retarders and Retarding Plasticizers

- Accelerators and Accelerating Plasticizers

- Air-entraining Admixtures

- Pozzolanic or Mineral Admixtures

- Damp-proofing and Waterproofing Admixtures

- Gas-forming Admixtures

- Air-detraining Admixtures

- Alkali-aggregate Expansion Inhibiting Admixtures

- Workability Admixtures

- Grouting Admixtures

- Corrosion Inhibiting Admixtures

- Bonding Admixtures

- Fungicidal, Germicidal, Insecticidal Admixtures

- Colouring

- Admixtures

- Construction Chemicals

- Concrete Curing Compounds

- Polymer Bonding Agents

- Polymer Modified Mortar for Repair and Maintenance

- Mould Releasing Agents

- Protective and Decorative Coatings

- Installation Aids

- Floor Hardeners and Dust-proofers

- Non-shrink High Strength Grout

- Surface Retarders

- Bond-aid for Plastering

- Ready to use Plaster

- Guniting Aid

- Construction Chemicals for Water-proofing

- Plasticizers (Water Reducers)

- Retarding Plasticizers

- Waterproofing Adhesives for Tiles,

- Marble and Granite

- Silicon-Based Water Repellant

- Materials

- Injection Grout for Cracks

- Concrete Repair System

- Fresh Concrete

- Factors Affecting Workability

- Measurement of Workability

- Slump Test

- Compacting Factor Test

- Flow Test

- Flow Table Apparatus

- Kelly Ball Test

- Vee Bee Consistometer Test

- Segregation

- Bleeding

- Setting Time of Concrete

- Process of Manufacture of Concrete

- Mixing

- Maintenance of Mixer

- Transporting Concrete

- Underwater Concreting

- General Points on Using Vibrators

- Height of Concrete Layer

- A depth of Immersion of Vibrator

- Vibrating near the Formwork

- Vibrating High Walls and Columns

- Vibration of Lightweight Concrete

- Curing of Concrete

- Curing Methods

- Water Curing

- Membrane Curing

- Application of heat

- Miscellaneous Methods of Curing Finishing

- Strength of Concrete And Effect Of Creep

- Methods of Controlling Sulphate Attack

- Corrosion Control

- Testing of Hardened Concrete

- Comparison between Cube and Cylinder Strength

- Determination of Tensile Strength

- Nondestructive Testing Methods

- Concrete Mix Design

- Statistical Quality Control of Concrete

- CONCLUSION

Also Download

- A to Z Formula of Civil Engineering

- Project Report on RCC Over Head Tank

- Secant Pile Construction Project Report

- Calculation of Bricks Excel Sheet

- Nano Technology in Construction

- Precast Construction Presentation

- Bamboo used as a construction material (PPT)

- Aerated Autoclaved Concrete (PPT)

- Civil Engineering Formulas E-Book

- Prismatic Compass Surveying PDF Notes

- Project Report on Multi Storied Building

- Estimate of Materials and Labor Excel sheet Download

Leave a comment